Manufacturers’ Superpower: ‘X-Ray Vision’ into Your Processes

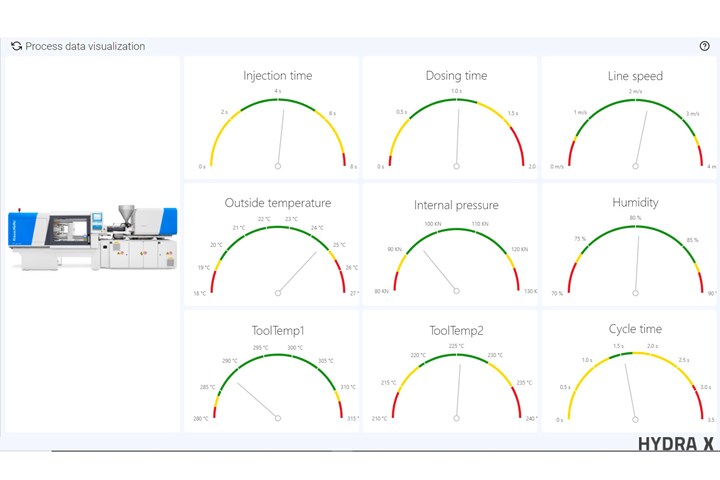

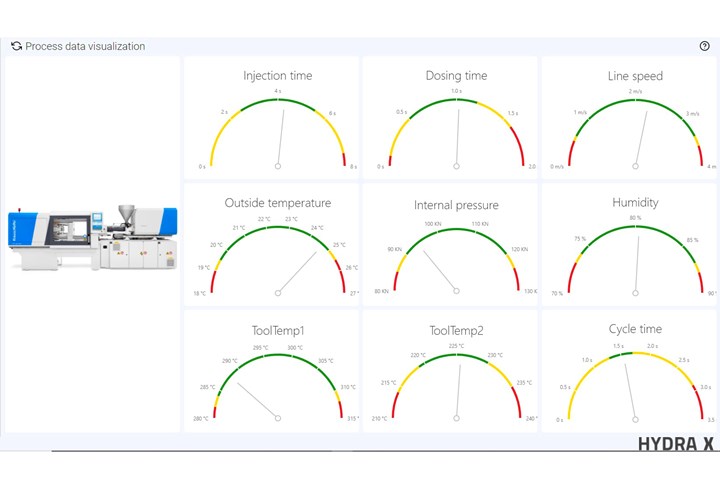

“Visibility” of processes and production is the key value of MES. MPDV’s Hydra X system is modular, allowing a user to “start simple” with one or two machines, just tracking uptime/downtime and cycle time and adding machines and functionality later on. (Photo: MPDV USA Inc.)

When I was five years old, I eagerly awaited the next broadcast of the “Superman” TV series. Among the Man of Steel’s arsenal of superpowers, my favorite was his x-ray vision, which allowed him to see danger brewing before it could strike. More recently, I have been reporting regularly on plastics manufacturers’ growing esteem for manufacturing execution system (MES) software that gives them figurative x-ray vision into the workings of their plant operations. Processors have told me they save a small fortune by being able to see the status of jobs in the production schedule and which machines are running slow or have gone down, so problems can be rectified before hours of valuable production time can be lost.

In particular, I have written about several trimmed-down “MES-lite” machine-monitoring systems (Guidewheel, IMM-Data, Datanomix, MachineMetrics) whose attraction is simple, quick-to-launch systems that require little employee training or installation effort. These are offered as alternatives to more elaborate MES and ERP (enterprise resource planning) systems that require heavy inputs of time and cost to implement.

Just this week, I was introduced to a company that positions itself somewhere in between these two poles of the manufacturing software market. I moderated one of our weekly Plastics Technology webinars, which was presented by MPDV USA Inc. in Orland Park, Ill., near Chicago. Quentin Cate, director of sales and marketing, and account executive Ron Esmao were presenting their Hydra X MES system. MPDV was a completely new name to me, but it turns out that the firm was started in Germany in 1977 and has been in the U.S. for 15 years. Quentin (who previously spent 10 years with IQMS) says MPDV is “very big in plastics” in Germany, though also active in metalworking and automotive, as well as medical devices, textiles and food/beverage production. All told, MPDV reportedly has 80,000 machines connected globally, including both primary and secondary or auxiliary equipment.

MPDV’s flagship product, Hydra X, was introduced in 2021 as “the next generation of MES.” It’s key distinction is that it is “not monolithic,” but a “platform-based” modular system. The foundation is MPDV’s Manufacturing Integration Platform (MIP), to which can be added over 120 manufacturing apps (“mApps”) from MPDV and a partner network of more than 35 software vendors. These are available through MPDV’s own app store, called the MIP Marketplace.

The upshot of this, according to Cate, is: “Don’t be afraid of MES.” A user can start simply with monitoring just uptime/downtime and cycle time on one or two machines or manufacturing lines. Then it’s possible to add more machines or lines and functionality via mApps such as MPDV’s FEDRA Advanced Planning System (APS), for scheduling simple or complex jobs and projecting material needs. The wide variety of mApps takes Hydra X “far beyond a classic MES,” Cate says, with functions such as AI-based setup-time prediction, AI-based capacity-utilization analysis by shift, assembly management and control, energy demand planning, FMEA failure mode analysis, inspection planning and inspection equipment management, human resources (HR) management, maintenance management, materials management and predictive planning, SPC and quality management, supplier evaluation, time & attendance, tracking & tracing, complaint management, workforce planning. If users already have their own systems for ERP, PLM, scheduling, etc., MPDV’s platform is designed to interface with them. (In 2020, MPDV joined the Open Industry 4.0 Alliance, which has 100 members.)

Ron Esmao notes that another simplifying feature of Hydra X is that the same basic interface is used for both the shop floor and manager’s office, with screens easily configured for different users. The system is also available on mobile devices, and data can be exported to Excel for additional analysis.

In the webinar, Cate cited a study by MPDV of 150 users, 75% of which reported that the number-one value of MES to them was “visibility” of their operations. Cate said that visibility is becoming ever more important as manufacturing becomes more complex and products acquire more value-added during production, which makes scrap and waste more costly. In addition, machines are getting smarter, which means they generate more data. And most shops utilize a variety of different machine technologies, brands, and ages. (One MPDV customer in the Chicago area has linked the system to a machine built in the 1920s.) MES can centralize production info from all these components and provide a single window into how well things are running — tracking orders, parts produced, machine status, scrap, tool usage, material usage, quality and process data, OEE and profitability.

MES can track the critical factors that affect your bottom line, which Cate lists as machines, labor, setup and downtime. “A lot of money is being lost when lines are waiting for material, tooling, or a setup technician,” he says. During initial evaluation of the system, one customer told MPDV that its setups typically took about 2 hr at a cost of $200/hr in lost production. But tests by MPDV showed that setups often really took 3 hr, costing the company a lot more than it knew. “Machine data doesn’t lie,” Cate concludes.

RELATED CONTENT

-

Injection Molding: How Repeatable is Repeatability?

Process repeatability is not a constant, but varies over time in response to a number of variables. That variation is not captured by a snapshot in time—measuring a discrete sample of parts. And the only way to manage that variation is with process controls that adjust each and every cycle.

-

Switch Over To Consistent Quality

A new process-control method picks up variations in melt quality and viscosity during the injection phase and equalizes them within the same shot.

-

Go Beyond SPC For Molding Process Control

A new real-time statistical analysis system for injection molding reportedly provides a new level of fault detection and process quality.

Leave a Reply