Solvay and Airborne Receive Funding for Composite Alternative to Metal Battery Enclosures

Solvay has secured major funding from Innovate UK, the United Kingdom’s national innovation agency, for its Battery Enclosure Materials Automation (BEMA) project. In partnership with Airborne, a leader in advanced composites manufacturing technology using automation and digitalization, the project aims to develop an all-composite solution for energy-efficient battery packs.

The collaboration has already received letters of support from Jaguar Land Rover and Vertical Aerospace. They see great potential in the design of more compact and lightweight enclosures for high-energy batteries in future electric cars and aircraft. The companies also are interested in the sustainability aspect of this project, which aims to reuse composite waste.

Advancing manufacturability of composite battery enclosures

“There is a pressing need to meet net-zero emission regulations and targets with more energy-efficient electric powertrain and propulsion solutions,” said Mark Wright, EMEA automotive sales manager at Solvay Materials. “While already lending structural and weight saving advantages over metals in existing EVs and aircraft, fully composite battery designs for larger production volumes have yet to show their technical and manufacturing feasibility. BEMA seeks to deliver on these challenges by combining the benefits of Solvay’s advanced thermosetting material technology with Airborne’s expertise in flexible automated composite manufacturing systems to create lightweight next-generation battery packs. This will provide a significant step-change toward higher energy efficiency at reduced size,” said Wright.

Shortening the design cycle

“As the demand for industrial quantities of composite battery enclosures grows, the challenge is to shorten the design phase and provide design-for-automation guidance,” said Airborne Commercial Director Joe Summers. “Working with Solvay will build material characteristics into design-for-manufacture rules for our multi-material automated ply placement technology, and subsequently allow us to connect our adaptable automation platform with intelligent planning and optimization.”

BEMA is currently in a pre-industrial testing and evaluation stage. Mechanical impact, shielding, thermal, and fire performance tests are underway at Solvay’s Composite Materials Application Centre in Heanor, UK, and with external service providers. In the next phase, prototypes will be produced to validate the new composite battery enclosures in field trials and obtain proof of concept for industrialization. The project will also address rate capability, cost, and sustainability challenges. Tangible and dependable results are expected within an overall project time of two years.

Image

SOLPR052a 1540×800.jpg

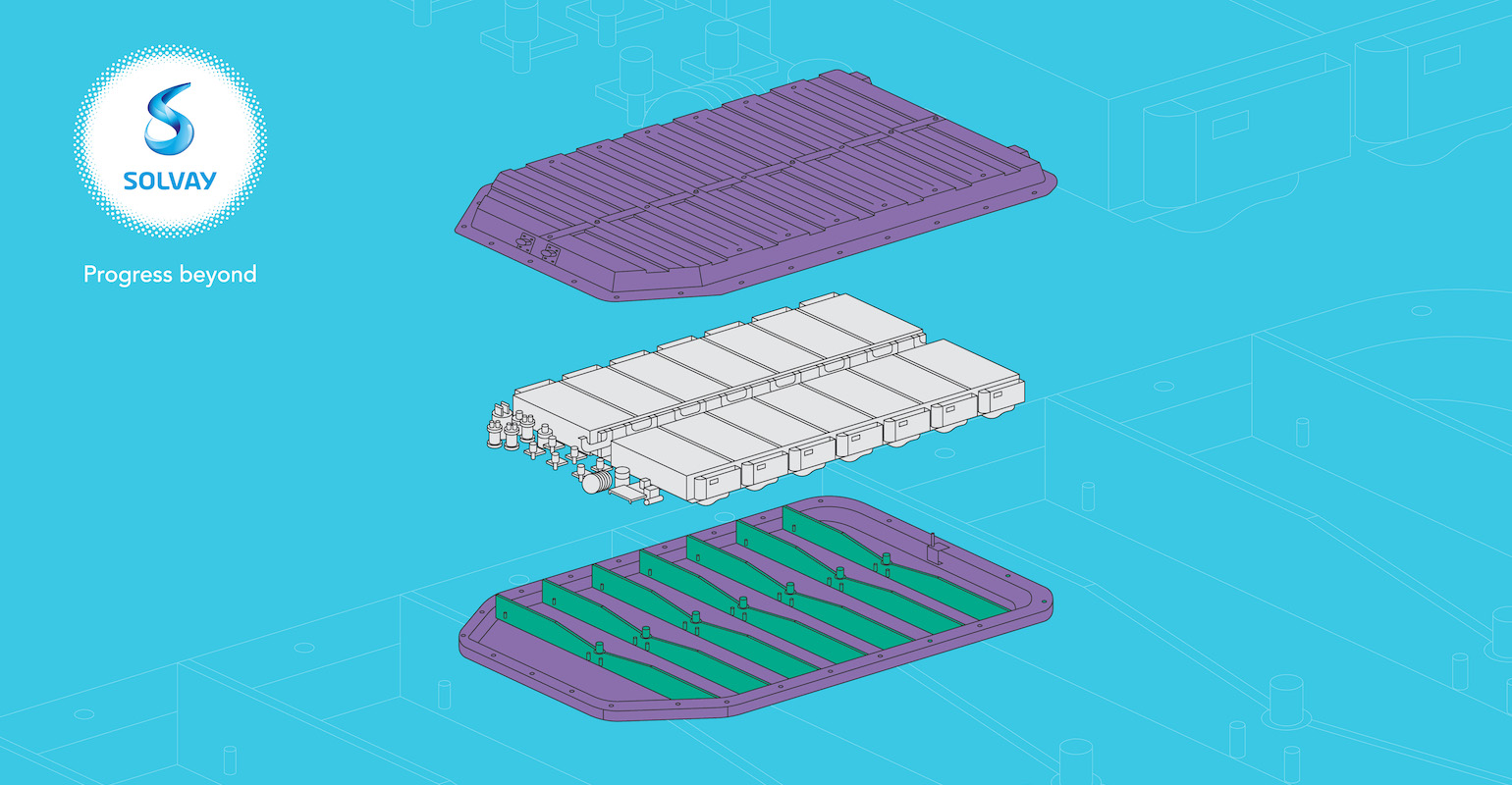

Solvay’s composite material battery enclosure design concept. Image courtesy of Solvay.

Leave a Reply