Tiny Part Showcases Big Molding, Moldmaking Capabilities

Matrix Tool (Fairview, Penn.) figured the best way for it to showcase its advanced moldmaking capabilities and the unique abilities of its Sodick Plustech injection molding machines was to create a showcase part and mold.

That part is just one of the entrants in the inaugural Hot Shots injection molded part competition, which will take place during the Molding 2021 Conference later this month in Chicago (Sept. 21-23; Donald E. Stephens Convention Center; Rosemont, Ill.).

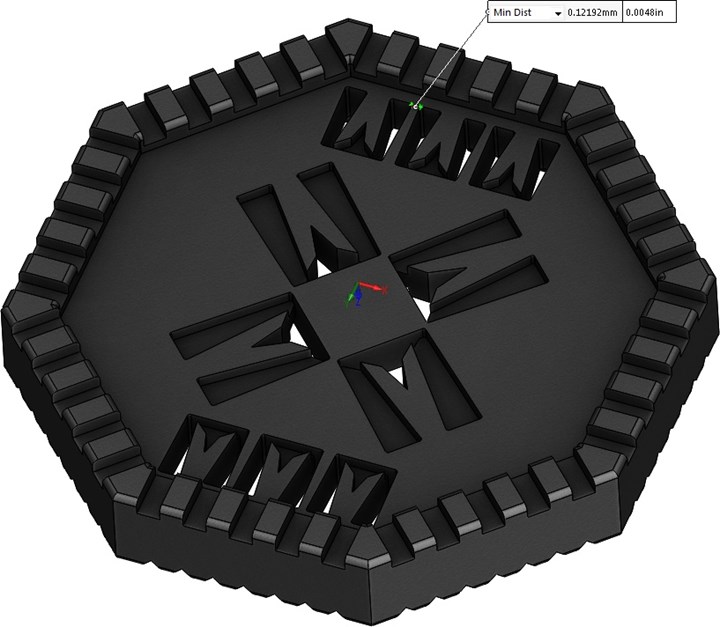

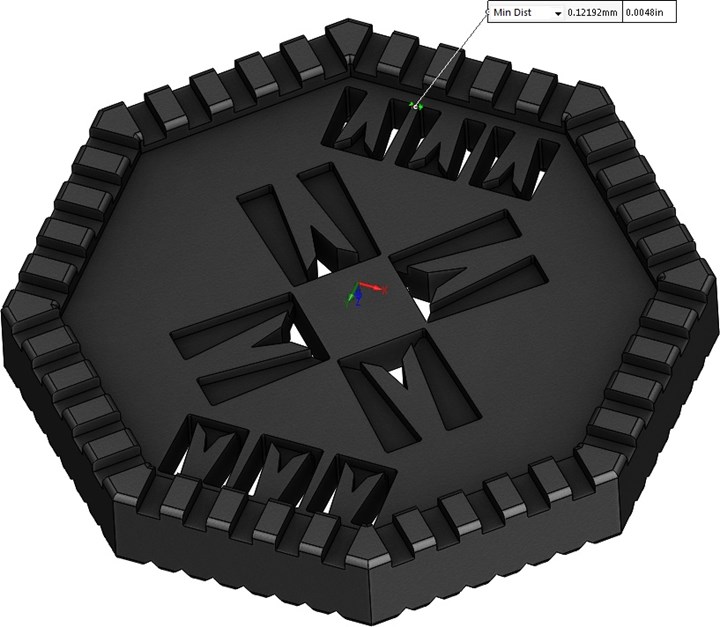

Molded from Sumitomo’s Sumika Supra LCP on a two-stage Hi-Response injection molding machine from Sodick, the showcase part has a wall thickness of just .007 inch, and is filled in 0.16 second with a 2.9-sec. cycle time.

Matrix designed this tiny LCP parts with intricate geometry to showcase the advantages of small tools and fast clamping, which its says can out produce larger machines running high cavity tools. Listen in to my conversation with Tom Moyak and his team at Matrix, as well as Len Hampton of Sodick, to learn more about this Hot Shots entrant, and register today for Molding 2021 to see all the parts in person in Chicago.

Matrix Tool and Sodick Plustech have entered this unique LCP part with micro features into Molding 2021’s Hot Shots part competition.

RELATED CONTENT

-

Best Methods of Molding Undercuts

Producing plastics parts with undercuts presents distinct challenges for molders.

-

How to Stop Flash

Flashing of a part can occur for several reasons—from variations in the process or material to tooling trouble.

-

How to Set Barrel Zone Temps

Start by picking a target melt temperature, and double-check data sheets for the resin supplier’s recommendations. Now for the rest…

Leave a Reply