Barr, CompuMold win top AMBA honors

Tom Barr, president of TK Mold & Engineering Inc., was named Mold Builder of the Year. CompuMold Tool & Design Inc. wins Tooling Trailblazer of the Year.

Tom Barr, president of TK Mold & Engineering Inc., was named Mold Builder of the Year. CompuMold Tool & Design Inc. wins Tooling Trailblazer of the Year.

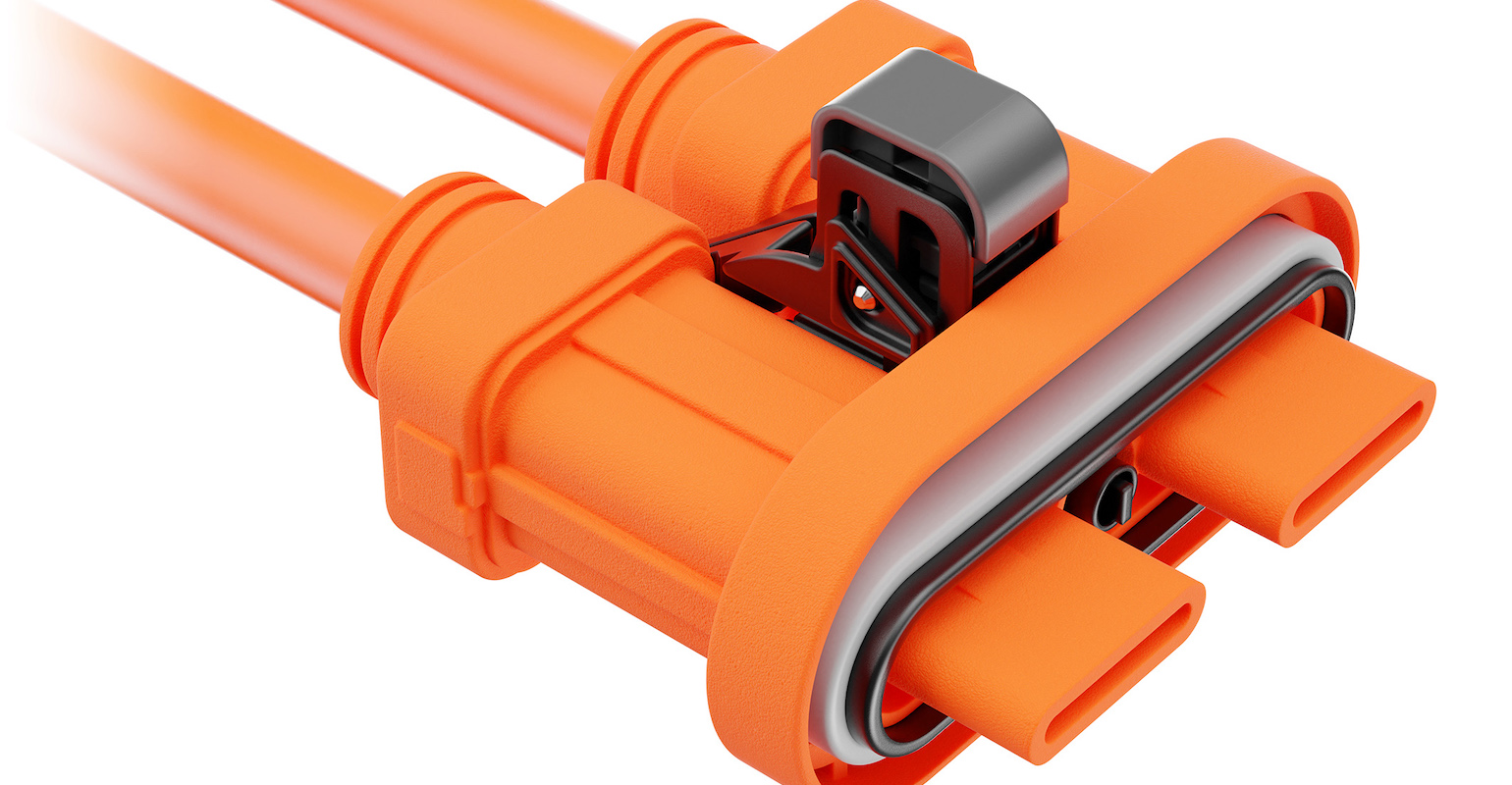

High-voltage components are usually exposed to significant and repetitive temperature fluctuations, which normally lead to strong discoloration in conventional polyamides (PAs). In contrast, polybutylene terephthalate (PBT) largely guarantees color stability, especially for the in-demand orange color (RAL 2003) desired by automakers, with no apparent color fluctuations or yellowing during heat aging. With its latest offering, however, BASF is expanding its portfolio of flame-retardant engineering plastics for the e-mobility market and…

The versatile new R3 thermoforming packaging machine developed by Multivac is designed to process recyclable single-material films consistently and reliably with minimal maintenance. The machine also features a modular construction such that it can be easily adapted to suit a range of customer requirements. The objective in designing the R3 thermoformer, which will be available starting in July 2022, was to find “best-fit” machine configurations for small and medium-sized companies…

The American Mold Builders Association (AMBA) has named Tom Barr, President of TK Mold & Engineering Inc., the Mold Builder of the Year, and CompuMold Tool & Design Inc. the Tooling Trailblazer of the Year. The awards were presented during AMBA’s annual conference on May 11 to 13 in Itasca, IL. Sponsored by Progressive Components, the awards include a $5,000 endowment to each winner for continuing education in mold building…

The plastic packaging and engineered materials company is seeking a further reduction in Scope 3 GHG.

The property, with 405 parking spaces and two loading docks, was assessed at $5.85 million, according to local media reports.

Arburg managing partners (l-r) Renate Keinath, Michael Hehl and Huliane Hehl with symbolic checks to Doctors Without Borders and SOS Children’s Villages. I deal in words for a living, but it’s said that actions speak louder than words. So I can’t say much to add to these actions: In April, family-owned plastics machinery company Arburg in Germany launched a company-wide fundraising effort to support a local Ukraine aid fund. The…

Streetsboro, Ohio-based toymaker Step2 had announced plans to close the plant in December.

Japanese firms Mitsui Chemicals and Microwave have developed what they call “an innovative, eco-friendly carbon-fiber (CF) manufacturing technology using microwaves.” The new process employs microwaves to heat the polyacrylonitrile (PAN) fiber precursors, both during the oxidation process — the most energy-intensive part of CF production — and during subsequent carbonization. As well as employing more compact equipment, the new technology cuts energy consumption by approximately 50% and offers a substantial…

In many injection molding applications, the user manually sets the mixing ratio of the base material, additives, and masterbatches typically on a separate control unit mounted on the press. This works just fine, until it doesn’t. The steps involved create multiple opportunities for error. Injection molding machine maker Engel and Werner Koch Maschinentechnik, a supplier of auxiliary equipment for plastics processing, have collaborated in the development of an OPC UA…