Rehau selling Russian operations as Ukraine invasion continues

“The development of the past weeks has made further decisions unavoidable,” Rehau officials said in announcing the sale.

“The development of the past weeks has made further decisions unavoidable,” Rehau officials said in announcing the sale.

Concentrated product formulas offer an effective way of reducing the environmental impact of packaging by using refillable containers. Weener Plastics (WP) responded to that sustainable trend by developing a small, handy refill pack that screws directly onto the threads of a pump or spray bottle. It consists of an injection-molded polypropylene refill package with a two-piece, child-resistant closure for enhanced safety. The refill pack is conveniently screwed onto standard bottles…

An early “scoop” of mine was a 1975 report on the first use of a microprocessor in plastics machinery controls—for, of all things, a filament winder for composites. As I approach my 50th anniversary with this magazine in a couple of months, I may be permitted to indulge in some some reminiscences. When I think back on that stretch of time, one of the things that stands out for me…

Join us on June 28th at 2 pm (edt) for the Numbers that Matter Livestream NUMBERS THAT MATTER LIVE with Bill Wood, Plastics News Economics Editor Some key economic data points to the potential for a recession, or at least more volatility, for the U.S. economy and key plastics end markets. Bill Wood, an economist who has tracked plastics for 30+ years, will answer reader questions and discuss the…

Although it represents only a fraction of plastics consumption, poly(lactic acid), or PLA, is gaining traction as brand owners chase sustainability credentials. Created using lactic acid from the fermentation of sugars, PLA typically is described as biodegradable. And it is, technically speaking, but only under strict industrial composting conditions. While it may degrade in natural environments, the process can take many, many years. Fortunately, science marches on, and researchers in…

Silgan Holdings Inc. and Pretium Packaging LLC have made moves impacting workers in California and Pennsylvania.

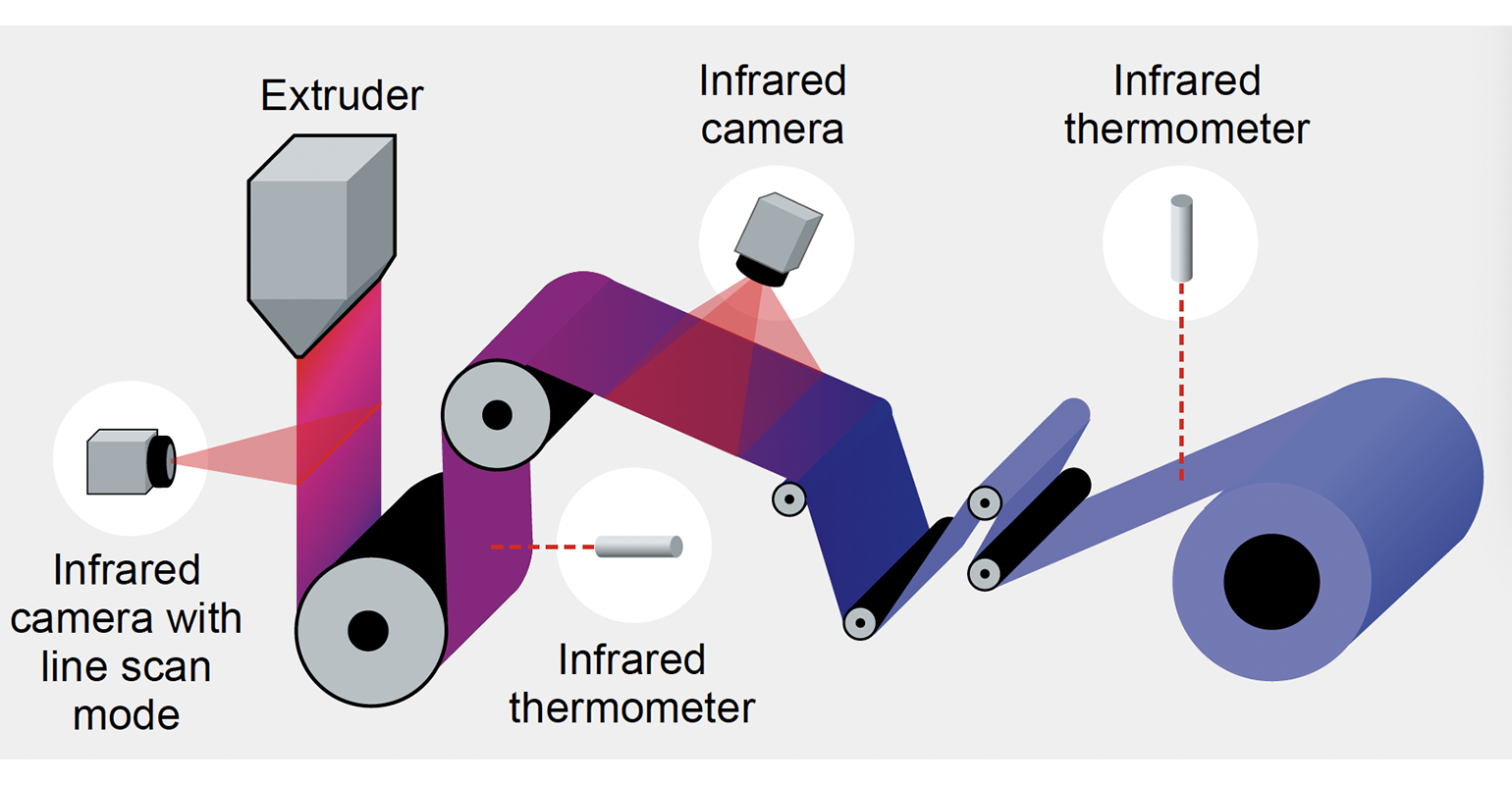

A lot can go wrong with temperature measurement during plastics processing and, by extension, the quality of your finished product. Even if you do everything by the book, errors can originate from ambient conditions. A new white paper from Optris explains how non-contact infrared (IR) temperature measurement technology can help to overcome these challenges. Plastics processors make products in various dimensions, thicknesses, textures, colors, and embossed patterns, notes the white…

Even as polymer 3D printing is increasingly being used for production, tooling remains a major application for 3D printing in the plastics industry. Exhibitors at the 2022 Plastics Technology Expo (PTXPO) were showcasing several examples of 3D printed tooling for injection molding. For mold inserts, 3D printing can aid in rapid prototyping, production molds with conformal cooling channels and mold repair. 3D printing can also be used to produce mold…

Detroit — Wittmann Battenfeld will feature its newest robot programming tool, the R9 Quick New Wizard, at the Injection Molding & Design Expo, May 25-26 in Detroit’s Huntington Center. R9 Quick New is designed to provide molders with an easier and more detailed tool for programming the functionality of their Wittmann R9 robots. The Quick New Wizard is a guided programming tool consisting of two components: • The first component…

C-sert LLC officials say stripped platen bolt holes can be a thing of the past with their line of patented threaded inserts.