3 Hot Manufacturing and Sourcing Trends Happening Right Now

The pandemic continues to drive interesting trends in the manufacturing universe, even as COVID-related restrictions ease and businesses across most industries are beginning to return to some semblance of normal. Earlier this year MD+DI spoke with Tony Uphoff, president and CEO of Thomas, about top sourcing trends he was seeing that impacted medtech.

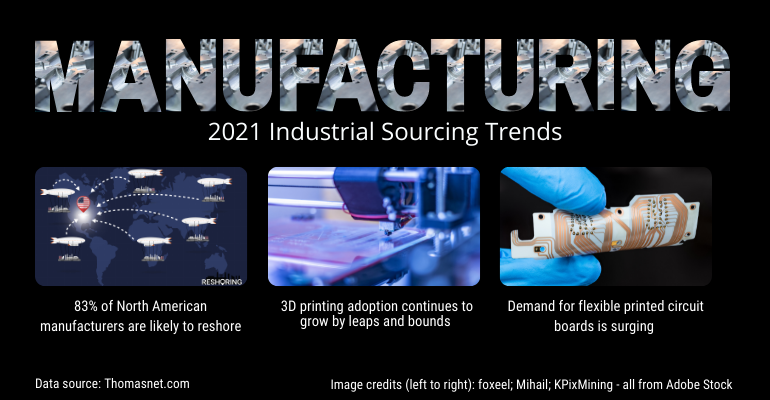

This week, we gained additional insights into current North American industrial sourcing and supply chain activity during a Thomas webinar that Uphoff led alongside Shawn Fitzgerald, the company’s chief marketing officer. The three takeaways that we found most relevant for the medtech industry are highlighted below.

Bringing manufacturing back to the homefront

In 2020, Thomas conducted a survey that found 54% of manufacturers surveyed were planning for North American reshoring. The firm conducted the same survey earlier this year and found that 83% of North American manufacturers are planning to reshore.

“We’ve all heard the promise of reshoring over the years. It is coming to fruition at this time,” Fitzgerald said. “And for all those folks on the phone in the manufacturing industry here in the U.S., the opportunity is coming straight at you, as they say.”

Uphoff said he and Fitzgerald often use the expression, “stop, drop, and roll moments,” which seems a fitting expression for this particular trend.

“I would double down on your points about the reshoring and the phenomenon that we’re watching,” Uphoff said to Fitzgerald during the webinar. “I think it’s very difficult when you’re in the midst of a market transition to actually see the size and scope of it, and we really strongly encourage manufacturing companies to understand the market opportunities laying before them, because arguably it is unprecedented over the last 100 years in North American manufacturing. Exciting times, to say the least.”

Most-sourced products

Out of 72,000 product categories that Thomas’ data covers, medical equipment and supplies ranked as the second most-sourced products. Printed circuit boards ranked number five, which is a technology that has increased in demand in the medical device manufacturing industry. Specifically, more medtech manufacturers are incorporating flexible printed circuit boards into their products. One reason for this is that flexible printed circuit boards are significantly lighter in weight and take up less space than traditional printed circuit boards.

3D printing surges

The demand for additive manufacturing (better known as 3D printing) equipment and services has also surged in a big way this year.

“We’re starting to see some real innovation, but boy the adoption of 3D printing is just absolutely taking off with manufacturers,” Uphoff said. “So there’s obviously an ease of production to it, it’s also about the different shapes that you can create, as we’re going through the digital transformation there’s a lot of AI and some level of machine learning that’s being deployed to try and rethink how to design certain components.”

He said additive manufacturing offers benefits over traditional manufacturing in terms of reduced weight because of the materials that can be used, as well as a wider range of shapes and patterns that can be produced using a 3D printer but would be physically impossible to produce using traditional manufacturing processes.

“It is very, very clear that we are witnessing a step change in the adoption of advanced manufacturing technology, and the digital transformation of manufacturing,” Uphoff said. “Many people refer to this as an umbrella term of industry 4.0 technology.” We’re predicing a pretty robust continued growth for 3D printers.”

Speed and flexibility are also benefits that come into play with the growing adoption of 3D printing, Fitzgerald said.

“When you look at products that are 3D printed, you’re also seeing the natural decline in price of the machinery, and the increase in complexity and capability that the machinery has right now,” he said. “You couple that with the natural trend of digital transformation that was accelerated to such a massive degree throughout the pandemic and you have this perfect storm of the increase of 3D printing and additive manufacturing.”

Leave a Reply