Acrylic Depolymerization Plant Reimagines Plastics Value Chain

Specialty material solutions provider Trinseo is advancing the potential of sustainable plastics with the inauguration of its next-generation polymethyl methacrylate (PMMA) depolymerization plant in Rho, Italy. Scheduled to be commissioned in Q1 2024, this demonstration facility marks a pivotal step toward reshaping the plastics ecosystem as part of the circular economy.

PMMA, or acrylic, finds use in applications such as consumer products, signage, automotive lighting, and building and construction. This depolymerization operation will be designed to enable the efficient recycling of end-of-life acrylic, as well as other difficult to recycle structures, which will ultimately be used to produce acrylic resins, sheets, and compounds containing recycled materials.

Complementing mechanical recycling

Depolymerization is a chemical recycling technology that is complementary to more traditional mechanical recycling processes. While mechanical recycling is vital to a successful circular economy, depolymerization creates brand new opportunities by reducing the polymer back to its constituent monomers. This allows for the recycling of a wider variety of PMMA-based materials, supporting an increase in recycled content and overall recycling rates and helping to reduce demand for virgin materials.

“Innovation in recycling technologies is imperative to effectively recycle various types of materials. This new facility is yet another major achievement toward a scalable system with the goal of making PMMA a truly circular material of high quality,” said Trinseo Chief Sustainability Officer Francesca Reverberi. “When combined with our own in-house sourcing and treatment of collected materials through our Heathland recycling operation, our PMMA depolymerization plant will offer a high-performance solution for a world increasingly looking for new ways to address sustainability in the plastics supply chain,” added Reverberi. Material produced using the depolymerization process will be integrated as part of Trinseo’s R-Life portfolio.

Chemical recycling activity accelerates

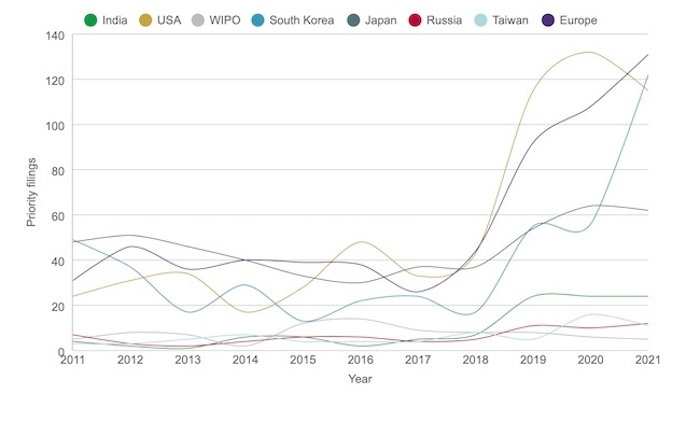

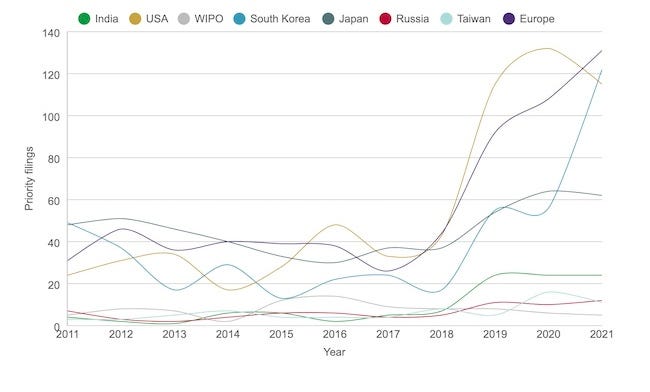

Appleyard Lee’s “Inside Green Innovation: Progress Report – Third Edition” on recycling details recent patent trends for chemical recycling, with the latest data indicating filing activities have been picking up, reaching an all-time high of around 500 in 2021.

The United States, Europe, and South Korea lead global patent filings for chemical recycling. Image courtesy of Appleyard Lee.

Eastman is now responsible for a 26% share of filings among the top 10 filers (and a 4.5% share of total global filings). While the number of Eastman’s patent filings has dropped by about 50% since 2019, the fall in its percentage share among the top 10 filers is greater because other companies have begun to file or increased their filings at a higher rate. Notable growth has come from Sabic, LG Chemical, and French research outfit IFP Energies Nouvelles.

Eastman has two core chemical recycling technologies:

-

Polyester renewal technology (PRT) takes polyester-based products, such as soft drink bottles, carpet, and polyester-based clothing, and unzips them back to their basic monomers. These monomers are sent through a polymerization process to make final products.

-

Carbon renewal technology (CRT) takes a broad mix of plastic waste — sometimes as diverse as mixed plastics, textiles, and carpet — and uses them as a material source. Then, that waste mixture is converted back to molecules and chemical building blocks to make a range of new consumer products. It can recycle most plastics (with the exception of PVC), many of which cannot be recycled with traditional mechanical recycling methods.

Leave a Reply