Adding Plastic Waste to Asphalt Reaps Environmental Benefits

Engineers at the University of Missouri (MU) are collaborating with Midland, MI–based Dow Chemical and the Missouri Department of Transportation (MoDOT) to develop and test asphalt pavement mixtures that incorporate plastic waste. The research aims to reduce plastic waste in the environment by integrating it with asphalt to pave US roadways and bridges.

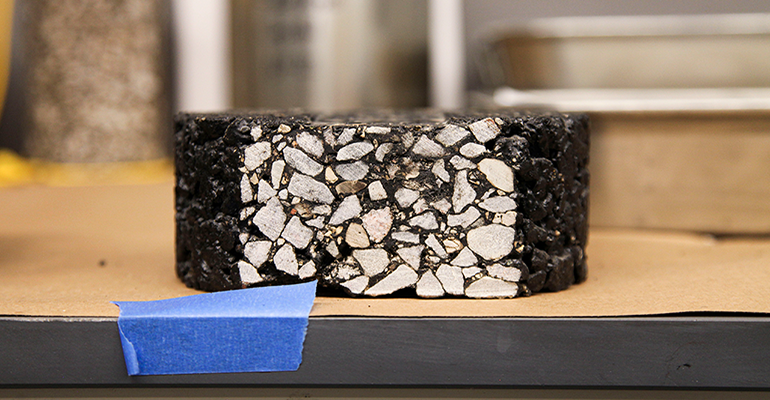

Researchers at the Mizzou Asphalt Pavement and Innovation Lab (MAPIL) in the MU College of Engineering are adding the plastic waste particles to pavement mixtures.

“Plastic was developed to be durable and has a shelf life of hundreds of years,” said Bill Buttlar, MU’s Glen Barton Chair in Flexible Pavements in the Department of Civil and Environmental Engineering and director of MAPIL, in a prepared statement. “Asphalt and plastics are also chemically similar because they both come from crude oil, so they can be mixed together. They aren’t perfectly compatible, but it’s close enough that engineers and chemists can work together to find a workable solution.”

Pavement mixtures typically contain asphalt and aggregates such as stone, sand, or gravel. But engineers and students at MAPIL are rethinking that traditional approach by incorporating various types of single-use polyethylene waste, including drinking bottles, straws, and grocery bags, in the mixtures. The idea emerged from a series of conversations between Buttlar and MU alumnus Jim Fitterling, Dow Chairman and CEO.

“This project fits perfectly at the intersection between both Dow and the University of Missouri’s purpose and mission,” Fitterling said. “At Dow, we’re working to tackle some of the toughest challenges facing our world, like ending plastic waste. These challenges will require great problem solvers and strong partnerships. I know we’re getting both when we work with the University of Missouri College of Engineering.”

Incorporating plastic waste in pavement mixtures will lower paving costs and benefit the environment by reducing the amount of virgin material in the pavement mixture. MoDOT currently uses recycled asphalt pavement, recycled asphalt shingles, and ground tire rubber in its pavement mixtures.

In real-world testing, MAPIL’s plastic waste–containing mixture is being used as a pavement overlay — a new layer of asphalt — on a deteriorating section of road surface in Columbia, MO, near the university. Traffic on the nearly two-mile test area averages approximately 36,000 vehicles per day. The team will observe the test area for at least one year.

The test also will include a control section paved with a current MoDOT-approved pavement mixture and a separate test section to trial a pavement mixture that incorporates chemically modified, recycled, ground tire rubber. Pavement overlay should last 10 to 15 years before needing to be replaced, and recycled materials such as plastic and tire rubber can extend that period by boosting strength and toughness.

“Everyone has a sense that this is a really big deal,” Buttlar said. “On the one hand, we appreciate plastics and we benefit from them, yet we are swimming in plastic waste right now. This is clearly a critical, global challenge where there are not a lot of viable solutions currently available. In this case, the pavement will have to be durable, economical, and truly sustainable.”

He added, “We’re now focused on studying the life cycle of plastic waste in pavement to make sure that it is a cleaner, more sustainable approach, and I think everyone senses that this is a possible solution.”

Leave a Reply