Can Plastic Recyclates be Welded Ultrasonically?

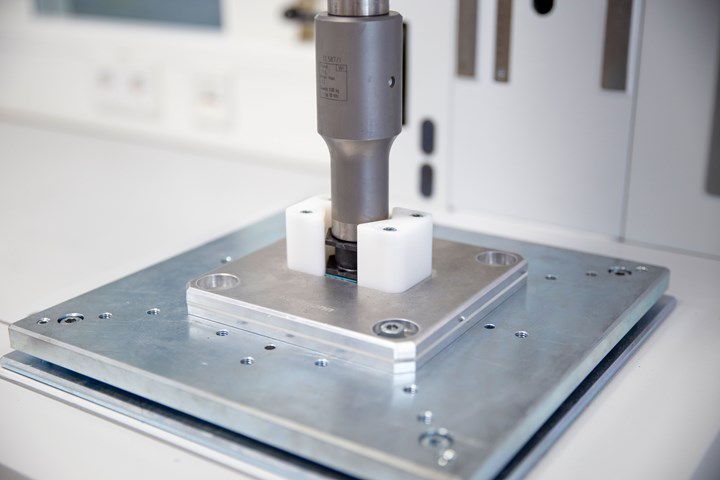

Photo Credit: Herrmann Ultrasonics and VDMA

Germany’s mechanical engineering industry association VDMA, as part of a series of interviews leading up to the K 2022 trade show in Dusseldorf next month, recently interviewed Jochen Ochs, head of application technology for plastics at Herrmann Ultraschalltechnik GmbH (Herrmann Ultrasonics U.S. office in Bartlett, Ill.). The topic: can recyclates be welded ultrasonically? Take a look at Ochs responses on the work they’ve done in this arena and its challenges.

VDMA: Can recyclates be welded ultrasonically?

Ochs: Whether and how well 100% recyclates can be welded depends on the material in question. It is difficult to make a general statement because each recyclate is different and multiple melting points can have a negative effect on the material properties.

We had test specimens made from a regranulate for our laboratory and found that we could use them to produce very good welded joints. In principle, we are therefore able to weld 100% recyclates with ultrasound.

VDMA: Why did you do these tests with plastic recyclate?

Ochs: We wanted to get a feel for what is possible with ultrasound. Will the result with recycled material actually be worse than with standard material? Do we have to adapt our technology? These were the questions we asked ourselves beforehand.

We offer this to our customers as an advance service. Before we receive a customer request to use recyclate, we wanted to know what we were up against. Now we have to see how the market develops and what kind of requests will actually be made to us in the future.

Two years ago, we already had conducted the type of tests we have now carried out on recyclates with bioplastics. For the same reason: we want to be prepared.

VDMA: How did you set up the recyclate project?

Ochs: The objective was to compare a standard nylon with a recycled nylon. First of all, we had to find a supplier who would provide us with regranulate. This was difficult because in our plastics laboratory we normally deal with standard (virgin) plastics. We finally located a manufacturer of high-quality plastic regrind from Baden-Wuerttemberg. With their regranulate, our partner Barlog was able to produce test specimens, which we compared with our standard nylon test specimens. We then set up a statistical design of experiments–a DoE, with 18 different parameter groups. We then tested tensile samples and compared them.

VDMA: What results did you get?

Ochs: We created cross-section views after each welding process. Initially, it became apparent that the recyclate looked rather worse in the cross section. A parting plane could be seen between the upper and lower parts. The standard material initially showed a much more homogeneous weld, with no parting planes visible in the sectional view – the part looks as if it were made from a single cast.

In preliminary tests, we found a parameter set that was suitable for both materials as initial parameter. We then created a DoE for this parameter set and welded five parts each with different parameter configurations. Finally, we obtained comparable results in the tensile test for both material types. In fact, we had expected the recyclate to get worse results, both in the cross-sectional view and for the tensile test. But there was a parameter set with which equally good results could be obtained.

VDMA: How important is it to know exactly which plastic recyclate you have?

Ochs: For us, the first thing that is important is that it is a thermoplastic. From the data sheet of the regranulate, you can read a few things, for example about mechanical and thermal properties. However, you cannot find a real indicator for the weldability quality in the data sheet. Only the test will show that.

That is also the reason why there are ultrasonic laboratories. Customers come to us for welding tests to check process properties and whether their requirements have been met. There is, of course, a lot of in-house experience due to many years of ultrasonics, so we can assess many things well beforehand. But when it comes to the weldability of recycled materials, we have broken new ground in our plastics laboratory.

Photo Credit: Herrmann Ultrasonics and VDMA

VDMA: You mentioned trials with bioplastics. What were the results there?

Ochs: As with the recyclate, we did not want to wait until a customer would approach us with such a project. At that time, we had test specimens made from three different bioplastics. Two were blends, i.e. not pure bioplastics, and one material consisted of one hundred percent biopolymers.

The tests showed that the blends were quite close to the standard plastics. The pure bioplastic only performed half as well in terms of tensile force. Nevertheless, the results were within a range that is sufficient for many types of applications.

VDMA: What impact would it have on the circular economy if it were possible to process recyclates and bioplastics on a large scale in the future?

Ochs: The mere fact that recycling takes place already has an enormous impact. There must be a change in thinking from the throwaway mentality and new production towards recycling. The world has used up its annual resources in just under seven months. With a significantly higher recycling rate, this could be changed.

Read: NPE2018 New Technology Focus: Sealing the Deal

If we recycled more or bought used goods, you can imagine that this would also have an immense impact on the economy. We are living much too large; the current economic system is based on the take-make-waste principle and is pushing our planet to the breaking point. The current shortage of raw materials also shows a dangerous dependence on this principle. The concept of a circular economy minimizes dependence on raw material imports, conserves resources and is a significant relief for the environment. Industry must adapt to these realities so that economic performance is not only maintained, but the savings potential of the circular economy is also reflected in higher productivity.

The world is facing major challenges: Climate change must be fought; the environment must be protected, and resources must be conserved. It is also important to make good use of the opportunities offered by digitalization. The plastics industry has a key role in this process because plastics are ubiquitous in the world. Climate protection, digitalization and the circular economy are therefore also the three major topics at K 2022.

Leave a Reply