3D Printing Slashes Unilever Bottle Design Costs

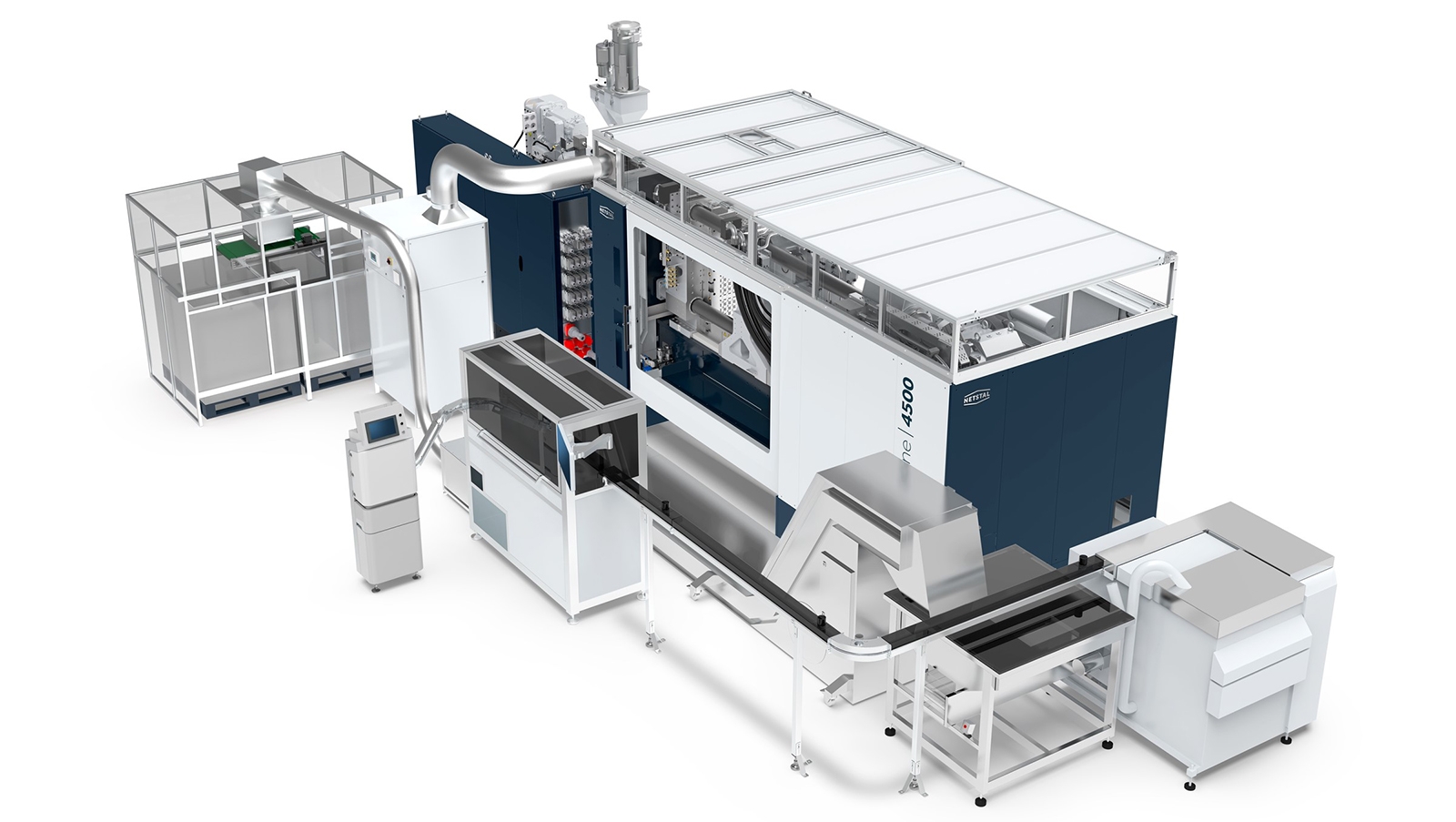

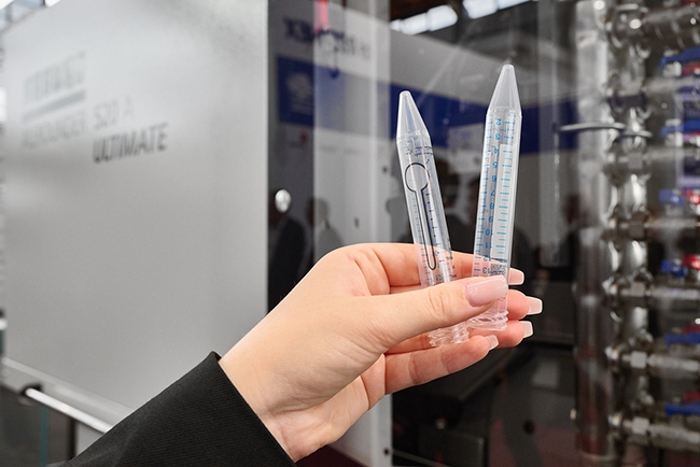

Unilever and plastic-packaging manufacturer Serioplast Global Services are transforming stretch blowmolded bottle prototyping using 3D printing technology from Formlabs. The result is much faster, less expensive mold making and prototype production and testing. Working together in Italy, Unilever and Serioplast used 3D printing to rapidly create molds and produce pre-production sample bottles made of PET. The molds were built using Formlabs’ Rigid 10K Resin and Form 3L large-format, stereolithography (SLA)…