World First: Manufacturer Runs 128-Cavity Mold in 1.9-second Cycle Time

A 128-cavity mold will produce 26-mm water closures in a cycle time of 1.9 seconds in a live experience at Netstal’s booth at NPE 2024.

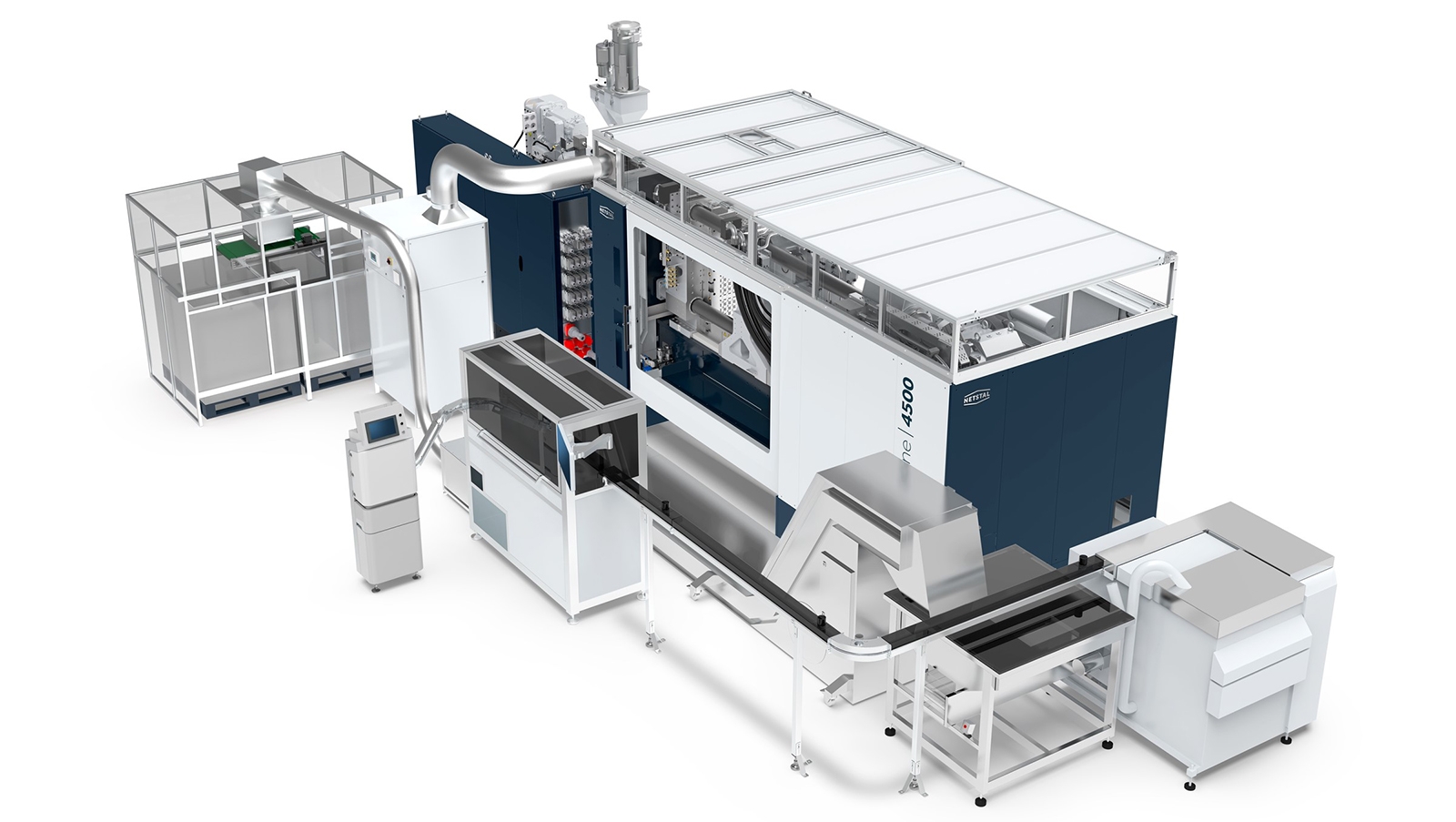

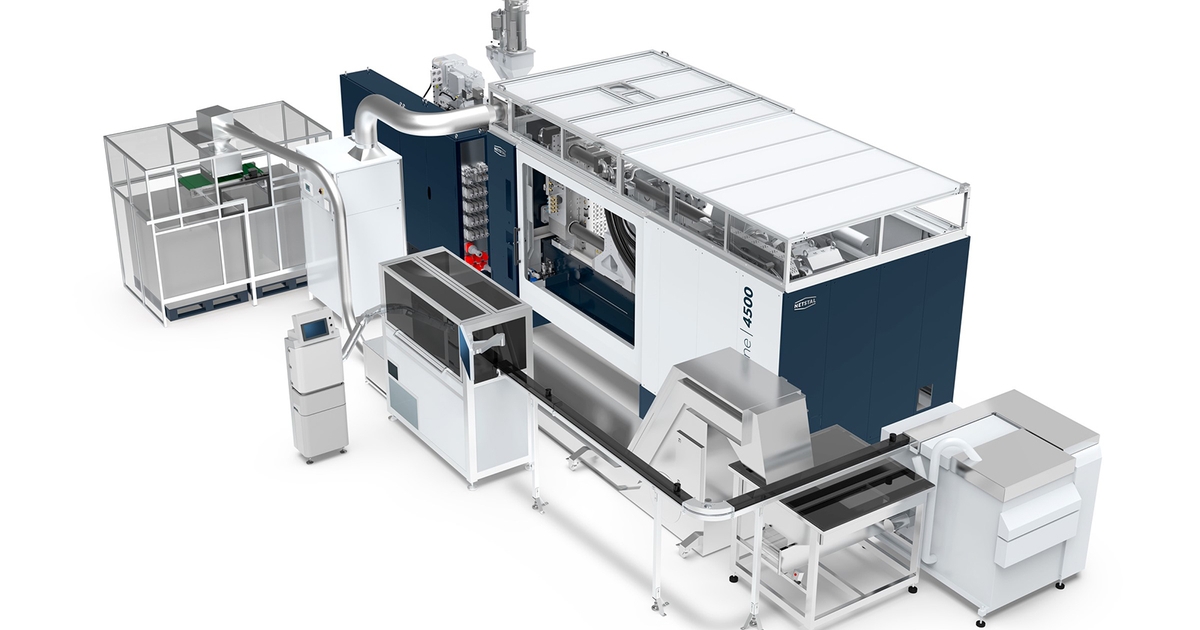

Netstal’s CAP-Line 4500 is identical to two production systems being used by Alltrista, a contract manufacturer based in Greer, SC. The line features an all-electric clamping unit with 4,500 kN of force and a dry cycle time of 1.4 seconds. An optimized barrier screw allows for a smaller injection unit with higher plasticizing performance and better homogenization, Netstal expained.

More than three billion closures produced annually

“Alltrista is the first in the world to produce with 128 cavities and a cycle time of 1.9 seconds,” said Horst Kogler, head of Netstsal’s caps and closures business unit. “They produce more than 3.1 billion closures with two lines [annually]. More output per square meter of production area is currently not possible.”

Enclosure weight reduced 25%

The mold, produced by Austria’s z-moulds, is as small and light as a 96-cavity mold and fits into the injection molding machine with a smaller column distance. Cycle time is reduced by the smaller design, which also requires moving less mass. Alltrista has cut the weight of its enclosures by 25%; with 3.1 billion closures produced annually, that means more than 2 million pounds less resin used – about the weight of 160 African Bush elephants, the company said.

In the NPE demonstration, finished caps will travel through an Intravis vision-inspection system. The system executes 360-degree inspection of the closures to an accuracy of hundredths of a millimeter using nine high-resolution cameras.

Overall, Netstal’s CAP-Line also fits in a smaller overall space — 538 square feet — and uses about 12% less electricity than competing machines running 96-cavity molds, Kogler said.

Accelerated machine delivery times

“With the new CAP-Line concept, we are aligning our portfolio even more closely with our customers’ applications,” he noted. “Closure manufacturers benefit from a customized system, while pre-configuration can speed up the consultation and quotation process so that delivery times for the machine are as short as possible.”

Added Christopher Navratil, CTO of Alltrista’s parent company: “We were determined to be the first manufacturer to run a system with 128 cavities in under two seconds. In Netstal, z-moulds, and Intravis, we have found the best system partners for this project. Each company is a leader in its field, and the combination is unbeatable. With our 128-cavity systems, we produce more efficiently than ever before, can deliver at any time, and inspire our customers. This has given us an enormous competitive advantage.”

Visit Netstal at booth W223 during NPE2024 at the Orange County Convention Center in Orlando, FL, from May 6 to 10.

Leave a Reply