Extrusion Basics: What Thanksgiving Leftovers Can Teach Us About Plastic Scrap

I hope you’ve saved the insides of the pumpkins you carved for Hallowe’en and will use them to replace other foods. That’s my way of saying SOS: Save our scrap. Plastic material — pellets, powder, or scrap product — is the “food” of our processes, and saving waste is seldom debated. But the economic angle must be remembered — it’s not just “out of sight, out of mind.” It must be stored cleanly and used wisely, just like pumpkin innards and holiday leftovers.

Hallowe’en is over, and with it the topic of ghosts and sugar-excesses managed or avoided, so we can look forward to Thanksgiving. We have a lot to be thankful for, but I remind you each year to be grateful for what you don’t have, be it disease or other troubles. If you’re a power-user — you feel more secure when you get people to do things for you — hold off for a day. We power-doers — more secure the more we can do for ourselves — may be helpful anyway.

My family once did a Thanksgiving dinner where we only used new-world foods. Turkey was okay but all too common, so we used salmon to remind us of the fish-dependent natives and immigrants. Corn was okay (we had never even heard of quinoa), and so were potatoes, tomatoes, beans, and avocado. Nothing from cow or sheep or pig, but bison (American buffalo) was okay. No sugar (origin New Guinea and India) but honey okay (bees everywhere). Aztec chocolate okay, but bitter. We now make intercontinental mixes with the same skill as plastic compounds. And we don’t waste much, either. Here are some useful ideas for maximizing the value of materials and minimizing plastic waste.

Keep it clean. Open scrap bins invite contamination, unless everyone really cooperates and/or the pieces are large enough to be hand-sorted at a granulator. Vacuum out used containers, use film liners, or do both. In a plant that uses polyethylene, liners can be chopped and recycled, too, but chopping film isn’t as easy as it sounds. That’s one reason why PE film isn’t recycled as much as possible.

Be aware of color. Most plastics yellow slightly when heated and many are deliberately colored. If you have a black application, put it all there. I once had a client who paid a bonus to salesmen to get orders for UG (Uncritical Gray).

|

Allan Griff

|

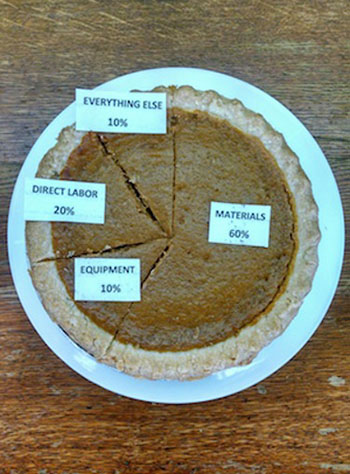

| This seasonal “pie chart” illustrates what really matters from a cost perspective in the extrusion process. |

Understand degradation. Heat processing breaks some polymer chains, which will lower tensile and impact strengths and raise the melt index, but remember HMM (How Much Matters). It may still be possible to use scrap at a low percentage; or add antioxidant or stabilizer to the original or scrap, using extrusion to allow a higher percentage of scrap; or lower melt temperatures to discourage chain breakage. A higher melt index will affect properties as well as some take-off systems. If you have an injection-molding department, it may be able to use it, but probably not vice versa. Extruding faster may help by cutting the time it is very hot, but if more rpm means hotter melt, you may not win. And it may not make any difference in end use, as these properties may involve some safety factors.

Watch particle size. Use the same granulator and screen; if you change, be alert for problems, especially in small extruders where channel depth in the feed zone is shallow enough to jam large particles and cause irregular feed. If inpush falls, adjusting the rear-barrel temperature may get it back.

Keep good records. Mark drums and boxes with as much as you know about the content, such as type of material, supplier’s product and lot numbers, date of extrusion, color, etc. It is also good to have duplicate records in a computer with physical location of the containers and maybe even an easy-to-find baggie of the contents.

Be proud of our reuse. There is much attention to reducing plastic waste now, which I support, but not because plastics are toxic, because they aren’t. I’m sorry this myth-understanding is so pervasive worldwide, and I have some ideas why — ask me if you’re interested — but I don’t see it going away. I’ll take the saving and rescue any way I can get it. That includes pumpkin in a pie, pumpkin fritters, and even ground pumpkin mixed with bison for all-American burgers or meat loaf. And, yes, I will have some intercontinental hot chocolate with that.

About the author

About the author

Allan Griff is a veteran extrusion engineer, starting out in tech service for a major resin supplier, and working on his own now for many years as a consultant, expert witness in law cases, and especially as an educator via webinars and seminars, both public and in-house, and now in his new audiovisual version. He wrote Plastics Extrusion Technology, the first practical extrusion book in the United States, as well as the Plastics Extrusion Operating Manual, updated almost every year, and available in Spanish and French as well as English. Find out more on his website, www.griffex.com, or e-mail him at [email protected].

No live seminars planned in the near future, or maybe ever, as his virtual audiovisual seminar is even better than live, says Griff. No travel, no waiting for live dates, same PowerPoint slides but with audio explanations and a written guide. Watch at your own pace; group attendance is offered for a single price, including the right to ask questions and get thorough answers by e-mail. Call 301/758-7788 or e-mail [email protected] for more info.

Leave a Reply