Fish Waste to Nano-Onions: New Milestone in Recycling ‘Garbage’

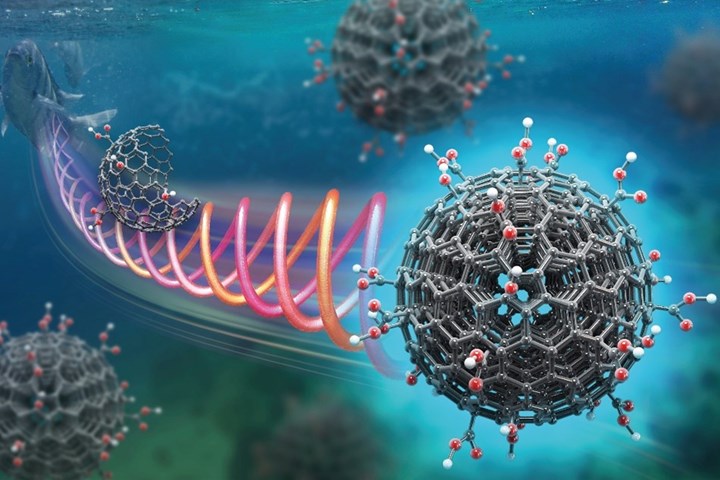

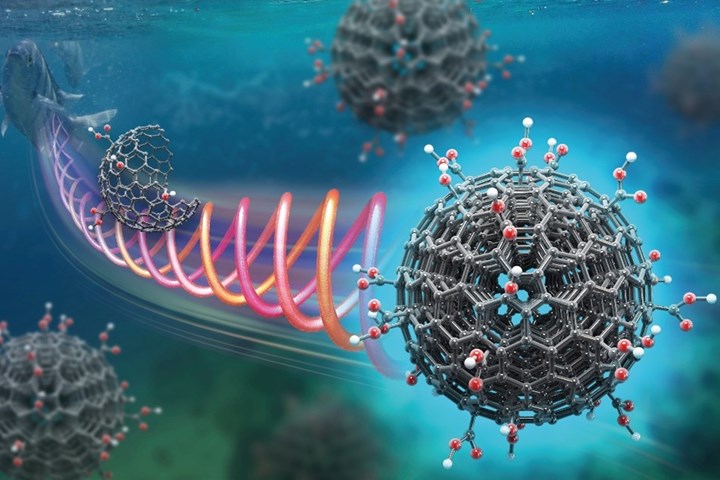

Don’t laugh. Nano-onions are real and really useful. Now they can be made simply and easily from an abundant supply of food waste. It’s the latest sign of a key trend in sustainable manufacturing. (Photo: Takashi Shirai/NITech)

I’ll start by confessing that this is not really about plastics, though it might be in the future. But it is a striking example of efforts underway to convert hitherto unusable organic refuse into industrial raw materials. Sawdust and inedible agricultural leftovers—e.g. “corn stover” (leaves, stalks, cobs)—are already being used to make biopolymers. There are also reported to be mountains of seafood waste—crab shells rich in chitin (a long-chain polymer)—that researchers have been trying to find a use for. Now, there’s a report that a team of scientists at the Nagoya Institute of Technology (NITech) in Japan has found that fish scales can easily be turned into industrially promising particles called carbon nano-onions.

Nano-onions? Just like the name says, these are nano-scale fullerenes, or quasi-spherical, polyhedral “soccer balls” of pure carbon arranged in multiple layers—graphitic soccer balls inside of soccer balls inside of soccer balls, etc. Carbon nano-onions, or CNOs are reported to have excellent electrical and thermal conductivity, and they have found applications in biomedicine, bio-imaging, energy conversion and electronics. But up to now, methods to produce them suffer from high complexity, toxicity and energy consumption. Various methods involve high temperatures or vacuum or considerable time and energy, or complex catalysts, expensive carbon sources or dangerous acidic or alkaline conditions.

Now comes a study in the British journal Green Chemistry, available online since April, which says the NITech team found a simple and convenient way to turn fish scales into high-quality CNOs. According to the report, cleaned fish scales can be converted into CNOs in less than 10 seconds through microwave pyrolysis, using no catalysts or harsh conditions. What’s more, this process yields CNOs with very high crystallinity, said to be very difficult to achieve with processes using biomass waste as a starting material. And the surface of the CNOs is selectively functionalized with carboxyl and hydroxyl groups, whereas other methods produce CNOs with a bare surface that requires secondary steps to functionalize. This combination of properties is said to result in exceptional optical properties not achieved with other CNOs. This advantage was demonstrated by the NITech team in LEDs and blue-light-emitting films.

The Nagoya researchers are not certain why fish scales are so easily processed into CNOs. They believe it has to do with the collagen in fish scales, which can absorb enough microwave radiation to heat up very quickly, leading to thermal decomposition (pyrolysis) and production of certain gases that support assembly of CNOs.

Now that I’ve recovered from how improbable all this sounds, I’m ready to ask, What’s next? I’m looking into my kitchen garbage pail and looking forward to an announcement of fabulous new industrial materials made from coffee grounds and used teabags.

Leave a Reply