Fungi Makes Meal of Polypropylene

Photo Credit: University of Sydney

Ongoing research into a variety of technologies for biodegradation of hard to recycle plastics is among the various avenues being taken by the industry and academia in their efforts to address plastic waste and the circular economy. Recently, two common strains of fungi were used to successfully biodegrade polypropylene in a laboratory experiment led by researchers at Australia’s University of Sydney, School of Chemical & Biomolecular Engineering. On the scary side, some science fiction film lovers might recall Michel Chrichton’s 1968 The Andromeda Strain and the 1971 film of the same name which fictitiously describe a microbe Phantom F-4. This biological agent recovered from a satellite and subsequently mutated degrades and destroys rubber-like materials in the aircraft including the pilot’s oxygen mask, and eventually the pilot as well.

The U. of Sydney researchers focused on polypropylene due to its high volume focused on PP due to its high volume use in such a broad variety of applications ranging from packaging, toys and other consumer goods to furnishings and automotive. They noted that PP ‘has long been recycling’s head scratching riddle’, and also that PP reportedly accounts for roughly 28% of the world’s plastic waste, but only 1% of it is recycled currently. They attributed PP’s infrequent recycling to its short life as a packaging material and because it often becomes contaminated by other materials and plastics, necessitating new recycling methods that have minimal environmental impact.

Overseeing the study, professor Ali Abbas from the School of Chemical & Molecular Engineering and chief circular engineer at Circular Australia said, “Despite the massive scale of plastic production and consumption, there has been very little attention paid to plastics degradation under environmental conditions, and our understanding of how plastics can be degraded is limited. One big question our result has raised is – what are the naturally occurring conditions which can fast track the degradation of plastics? We seek to further explore the role of biological processes offered by fungi and other microorganisms.”

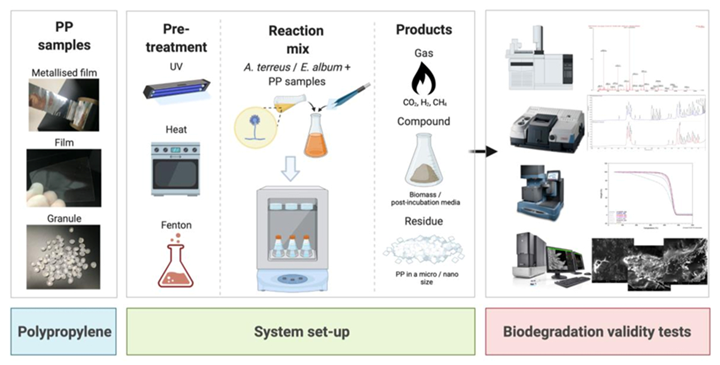

Typically found in soil and plants, the study found that two strains of fungi Aspergillus terreus and Engyodontium album were able to break down PP after it had been pre-treated with either UV light or heat, reducing the plastic by 21% over 30 days of incubation, and by 25%-27% over 90 days.

The researchers hope their method could one day reduce the vast amount of plastic polluting the environment and lead to a greater understanding of how plastic pollution might biodegrade naturally under certain conditions. Said PhD student Amira Farzana Samat and the study’s lead author, “Polypropylene is a common plastic used to make a huge variety of everyday products like food containers, coat hangers and cling film, but it only has a recycling rate of only one percent, meaning it is overrepresented in plastic waste and pollution globally.”

According to co-author of the study professor Dee Carter, an expert in mycology – the study of fungi – in the university’s School of Life & Environmental Sciences, fungi are exceptionally versatile and are known to be able to break down pretty much all substrates. Carter attributes this ‘superpower’ to fungi’s production of powerful enzymes, which are excreted and used to break down substrates into simpler molecules that the fungal cells can then absorb.

Said Carter, “Often, these fungi have evolved to break down woody materials, but this ability can be repurposed to attack other substrates – this is why we find fungi growing on all sorts of man-made materials like carpets, painted furniture, grout around tiles, shower curtains, upholstery and even car headlights. Recent studies suggest some fungi may even degrade some of the ‘forever chemicals’ like PFAS, but the process is slow and not yet well understood. There is also evidence that the amount of plastic accumulated in the ocean is less than what might be expected based on production and disposal levels, and there is speculation that some of this ‘missing’ plastic may have been degraded by marine fungi.”

Photo Credit: University of Sydney

The Method and What’s Next

Polypropylene in various forms was initially treated with one of three separate methods: UV light, heat, and Fenton’s reagent – an acidic solution of hydrogen peroxide and ferrous iron often used to oxidize contaminants.

In a petri dish, the fungi were applied separately as single cultures to treated PP. The validity of the biodeterioration was then confirmed through microscopy techniques. While the research didn’t evaluate how the plastic was degraded by the fungi or whether it was metabolized, the researchers hope to conduct further research to determine the type of biochemical processes taking place.

Professor Abbas, who believes the low rate of plastics recycling globally presents a ‘massive plastics circularity gap’ noted, “We need to support the development of disruptive recycling technologies that improve the circularity of plastics, especially those technologies that are driven by biological processes like in our study. It is important to note that our study did not yet carry out any optimization of the experimental conditions, so there is plenty of room to further reduce this degradation time.”

RELATED CONTENT

-

Hot-Fill Packaging: OPP and ‘Panel-Less’ PET Bottles Grab the Spotlight

Improved clarity and cost competitiveness, added to its inherent heat resistance, are reviving OPP’s prospects in hot-fill barrier containers. But hot-fill PET containers are raising the bar with higher productivity and ‘panel-less’ bottle designs.

-

How to Injection Mold Cyclic Olefin Copolymers

This new family of clear engineering thermoplastics made its first big splash in extrusion, but now injection molders are learning how to process these amorphous resins into optical and medical parts.

-

Melt Flow Rate Testing–Part 1

Though often criticized, MFR is a very good gauge of the relative average molecular weight of the polymer. Since molecular weight (MW) is the driving force behind performance in polymers, it turns out to be a very useful number.

Leave a Reply