Ineos, Barnes Partner to Optimize Molding of Recycled ABS

Two new grades of mechanically recycled ABS, featuring either 50% or 70% recycled content, promise to match the properties of prime materials and are the focus of a partnership intent on optimal molding of the materials.

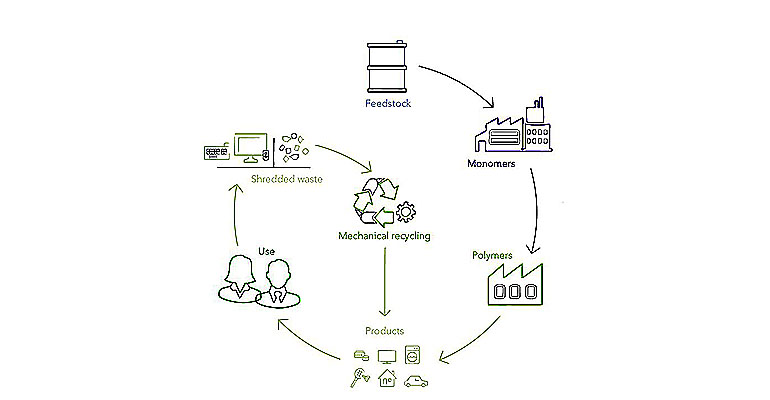

The grades — Terluran ECO GP-22 MR50 and MR70 — from Germany’s Ineos Styrolution are based on post-consumer waste electrical and electronic equipment and will be available in black. The materials are aligned with the company’s pledge to incorporate at least 325 kilotons a year of recycled materials into its products.

“We are convinced that our Terluran ECO is the best mechanically recycled ABS in the world,” said Yohann Bach, Product Director ABS Standard EMEA for Ineos Styrolution. “It offers identical properties to the respective native material.”

Terluran ECO materials are expected to match the mechanical properties of their respective prime Terluran grades, the company said, with no need for downcycling. They are intended to be used in the same applications as prime Terluran GP-22, including household applications and housings for electronic devices. ECO materials compare favorably in performance with prime GP-22, per the company’s data sheets. For instance, the tensile modulus of GP-22 is 2300 MPa vs. 2100 for both ECO variants.

Ineos will collaborate with Molding Solutions, a business unit within the Barnes Group, to explore how best to mold these sustainable materials.

“With our unique technology, we are able to expand our molding capabilities of post-consumer recyclate to meet the required product quality,” said Dr. Stefan Kruppa, Vice President of R&D for Molding Solutions. “Our aim is to enable customers to achieve the best results in the injection molding process with recycled ABS.”

Leave a Reply