Machine Intelligence Mobilized Against Waste

Last week, I had the pleasure of moderating a Plastics Technology webinar presented by Lukas Neunzig, plastics application engineer at Engel in York, Pa. He rather creatively – and perhaps whimsically – titled his talk, “2023: The Year Machines Will Take Over Molding.” That immediately grabbed my attention, and evidently intrigued 257 others who registered for the webinar. Flashbacks of the “Terminator” movie series – “The Rise of the Machines” – echoed in my head. (Shades of the Matrix series here, too.) His webinar title also evoked the mix of excitement and anxiety stimulated in recent weeks by public chatter about artificial intelligence (AI) “chatbots” that mimic human ability to carry out conversations or answer internet search requests in textual form.

The actual subject of the Engel webinar was the company’s suite of iQ software apps for controlling various elements of the injection molding progress. Engel and other major injection machine builders have been actively developing such programs in recent years. (See our reporting on such developments from Wittmann, Arburg and KraussMaffei, to name a few.)

As such self-regulating programs for injection machine control have proliferated, the arrival of “Autonomous Molding” (a phrase used by iMFLUX) has seemed more and more imminent.

I doubt that such talk inspires much quaking of the knees in this industry. I don’t think anyone fears a “Judgment Day” (that’s Terminator-speak) when the molding equipment and auxiliaries become self-aware and decide to banish error-prone humans from the molding plant. Nor do I see any parallel to the breathless speculation on how AI text-bots will steal jobs from people in various professions – all the less so considering the acute shortage of actual humans in plastics manufacturing.

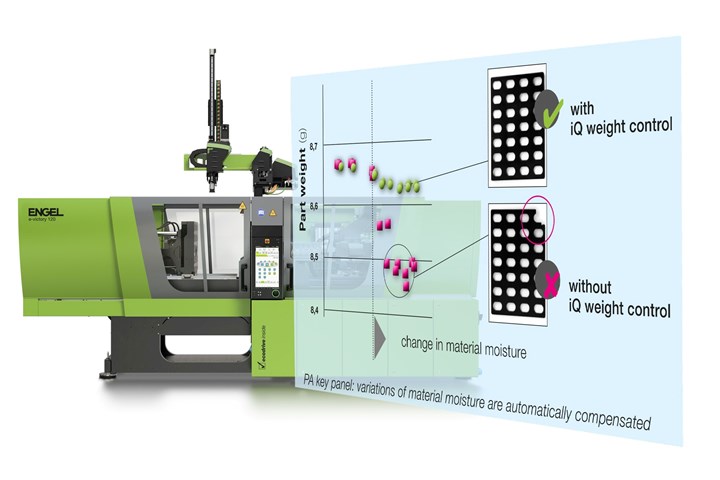

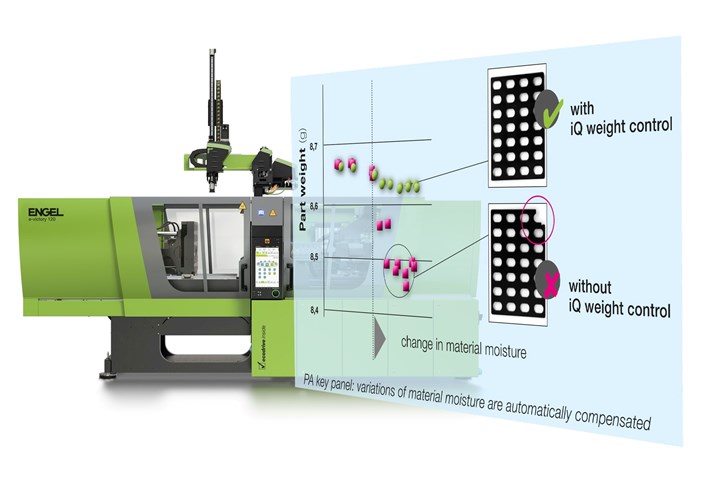

So I asked myself what these intelligent machine-control programs like those from Engel et al are really about. The first iterations, like Engel’s iQ weight control, were quite naturally aimed at maximizing part quality by ensuring consistent part weight. Subsequent developments – like Engel’s iQ melt control, clamp control, hold control and flow control – tackled specific elements of the process to cut down on wasted cycle time, energy, material (through overpacking), and maintenance costs of excessive wear and tear on machines and molds.

How do they do that? By extending screw-recovery time to utilize all the available cooling time, reducing wear and tear on injection units and overheating of the melt through shear. By reducing the clamp tonnage to just the amount necessary for a particular mold, saving energy and mold wear. By optimizing pack-and-hold time to neither undershoot nor overshoot gate-freeze time, preserving quality and saving energy. By regulating pump speed of a mold temperature-control unit (TCU) to provide just the flow required for adequate cooling – a really big energy saver, according to Engel. Even the quality-assurance aspect of iQ weight control (and similar programs from other suppliers) can be seen as really preventing waste – i.e., rejects and all the material, energy, labor and other inputs that go into any molding cycle that does not produce saleable product.

In the same vein, a Keeping Up With Technology news item to appear in our April issue (and available online now) reports on a new control option from Netstal that saves energy and wear and tear by minimizing system hydraulic pressure in the injection press to just the level required by the particular application.

Read: K 2022: ‘We’ve Been Waiting 40 Years!’

So, from that angle, all that machine intelligence can be viewed as directed primarily at waste avoidance – hardly a diabolical plot by The Machines to “take over molding” in the sense of taking it away from human control. Rather, it shows awareness by the human experts who designed the software of the common human fallibility – call it ignorance, laziness, or insecurity, if you will – that leads too many setup technicians to program the maximum screw-recovery speed, maximum clamp pressure, etc. as standard practice. All that waste. Today’s profit margins won’t support it. Somebody, or something, had to provide an alternative.

If a machine controller could chuckle …

Leave a Reply