New Electric Molding Machine Achieves Best-in-Class Speed, Precision

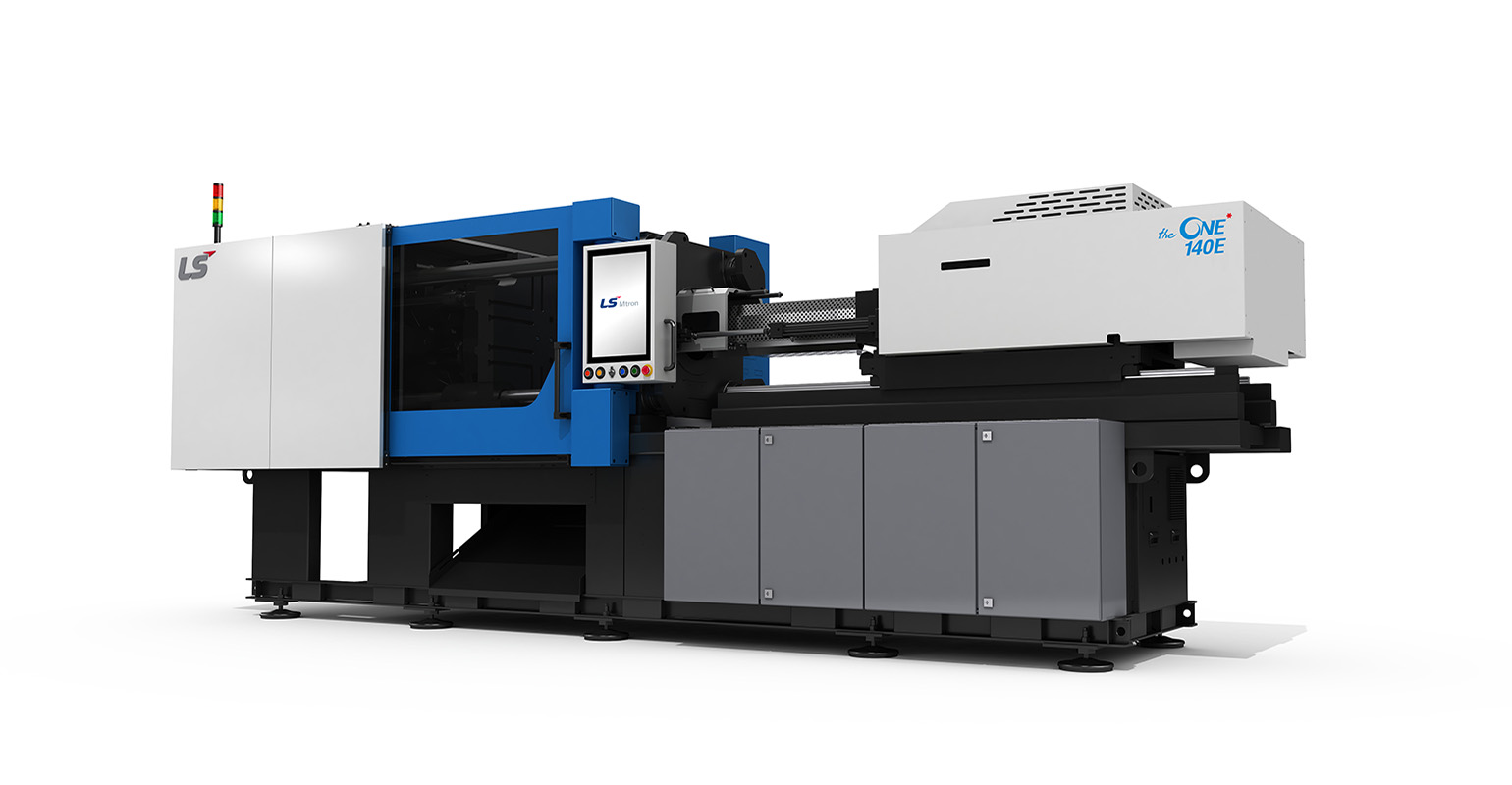

A new, all-electric injection molding machine featuring a toggle-link design achieves best-in-class speeds in the dry cycle, according to LS Mtron. The ONE*-E machine is suited for high-speed thin-wall molding and will be shown for the first time at Plastec West in Anaheim, CA, on April 12 to 14, 2022.

The ONE*-E line is currently available in five sizes — 120, 140, 190, 310, and 390 tons — with four additional models coming later this year.

Suited for packaging and medical, among other applications, the machines achieve fast cycle times and precise molding thanks to the new, optimized toggle mechanism. It allows a 30% faster link speed ratio and an industry-leading dry cycle time of just 1.49 seconds, said LS Mtron. It also has a smaller footprint than previous models.

A rigid, one-piece casting structure reduces machine vibration and provides enhanced durability and precise injection control. Injection acceleration time for thin-wall molding has been shortened from 78 to just 20 ms, and rotator inertia has been reduced by 74% through a low inertia design.

“We can now offer molders a world-class, all-electric, high-performance machine that is ideal for high outputs and fast cycle times,” said Peter Gardner, Business Director at LS Injection Molding Machine North America, a division of South Korea’s LS Corp. “It’s a perfect solution for thin-wall molding, packaging, and medical parts.”

The standard 18.5-in. iPad-type touch screen (a 21.5-in. version is available as an option) with swipe, pinch, and zoom functionality shortens the time of complex processes and improves product reproducibility, according to LSMtron. It has a user-friendly interface configuration and AI molding solution through automatic weight control software.

In addition to fast opening and closing actions, the ONE*-E monitors clamp force by a tie bar sensor (OPT), automatically calibrates the clamping force, and has an automatic zero-point adjustment mode for spring molds. The Dual Center Press Die structure minimizes deformation of the die plate and enhances distribution of surface pressure in the mold, helping to extend mold life, said LSMtron.

Grafting digital load cells improves not only the measurement control cycle but also reproducibility through high-speed/high-level pressure control.

Integration of the linear motion guide in the driving section reduces friction and has a positive impact on acceleration and precision control.

The machines are Industry 4.0 ready — users can engage LS Mtron’s CSI monitoring and control software to retrieve and control data.

The use of a next-generation dual-core CPU and separation of the architecture into main and HMI CPUs improved CPU load and allowed the addition of various modes, including:

- clamp-force optimization;

- high-speed, low-vibration clamping profile;

- high-speed injection;

- packing (or holding) pressure pattern selection;

- residual pressure elimination, in case of charging completion.

The ONE*-E all-electric injection molding machine will have its world trade-show premiere at Plastec West, one of five co-located events at IME West. The trade show and conference comes to the Anaheim Convention Center in Anaheim, CA, on April 12 to 14. The machine will be on display at the Hirate America booth (3911).

Leave a Reply