Röhm Puts on a ‘Light Show’ at Chinaplas

Celebrating its 90th anniversary in 2023, polymethyl methacrylate (PMMA), aka Plexiglas, from Röhm was showcased at Chinaplas 2023 in innovative applications in automotive, lighting, household appliances, and medical devices.

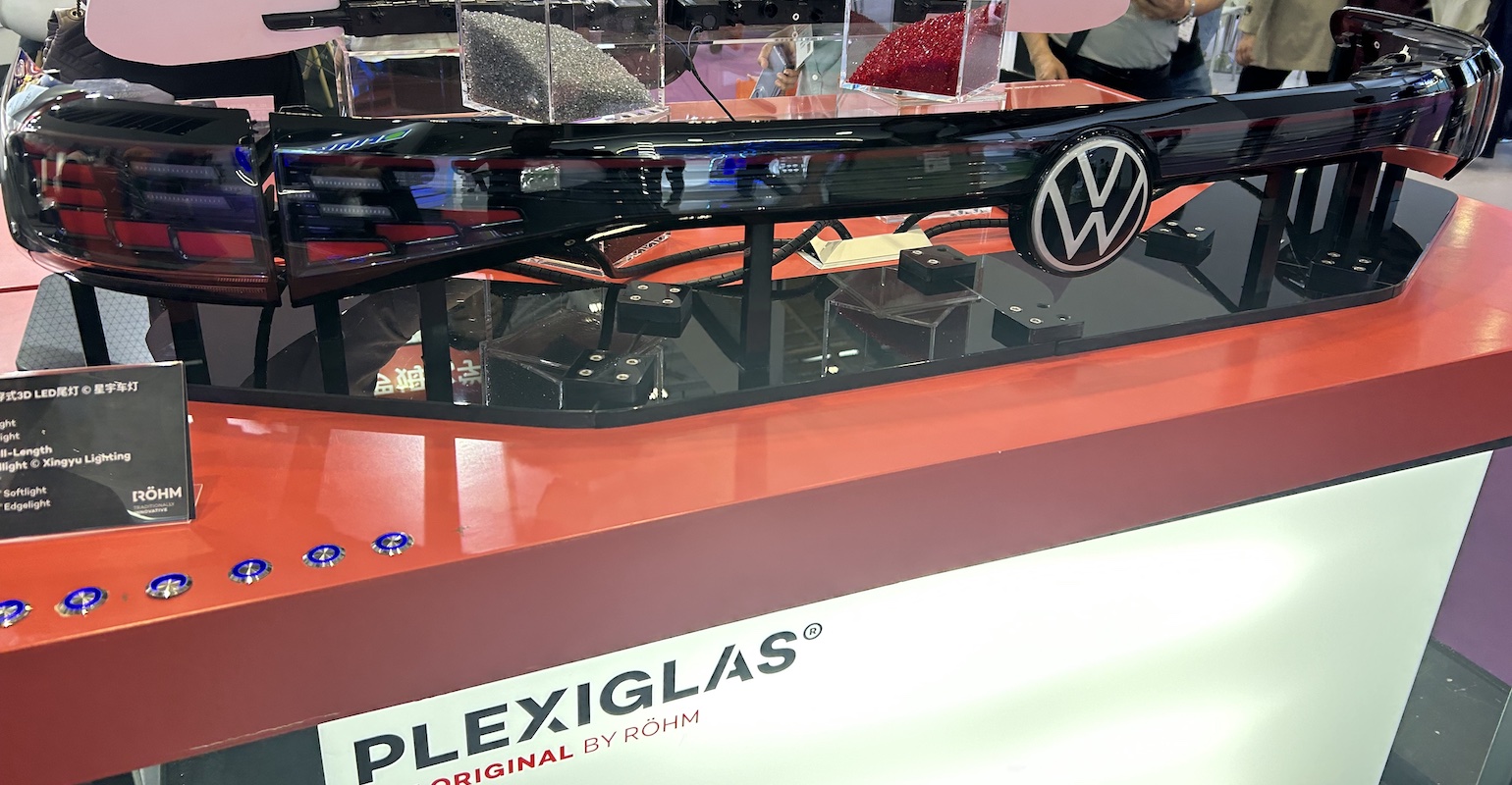

Since they started replacing glass in the mid-1950s, Plexiglas molding compounds have been used in taillight covers for more than 70 years. Over time, small, functional lights have been transformed into complex components for brand-specific signature lights, and Röhm has continued to develop its custom portfolio of special molding compounds to meet this demand. The company produces transparent molding compounds in signal colors or crystal-clear variants, as well as versions with heat deflection and light-scattering properties.

The molding compounds are said to be easy to process, even in conjunction with innovative procedures such as laser welding, a process that has increased freedom of design, enabling angular components to be combined with minimal joints.

Preventing chemical stress cracks

Full-width strip taillights are an increasingly popular choice for electric vehicles, but they are prone to chemical stress cracks. In response, Röhm offers chemical-resistant Plexiglas molding compounds to improve the yield and durability of complex automotive lights.

The design of automotive front ends is also changing, with long light guides, high-gloss panels, and logos replacing chrome. A vehicle front requires particularly robust, impact-modified materials. For illuminated applications, the Plexiglas Resist molding compound meets both optical and mechanical requirements. For high-gloss panels at the front of the vehicle, Plexiglas Hi-Gloss is a robust and resource-efficient alternative to components that need additional painting. Its weather resistance properties ensure a sophisticated appearance that lasts.

Gray Plexiglas molding compounds are the new black

Neutral gray Plexiglas molding compounds achieve a black panel effect, which transforms a black surface into a true-color display and gives automotive designers new design options for vehicle lighting. This heralds a new trend in the premium sector — taillights that only become visible when turned on. When the vehicle is turned off, they are not visible as separate components but are black, glossy panels that integrate seamlessly with the vehicle body. At Chinaplas, Röhm presented a new neutral gray Plexiglas molding compound boasting increased light transmittance in the red spectrum. With this, automotive suppliers can achieve the signal red needed to meet requirements for vehicle lighting with fewer LEDs, or with LEDs that require a lower energy intensity and, thus, contribute to sustainability.

Molding complex geometries

Another new product, Plexiglas 8N plus simplifies the manufacturing of complex injection-molded parts. Enhanced light transmittance, UV and weather resistance, and flow properties during processing impart application-specific benefits for molded parts with complex geometries.

For example, Plexiglas 8N plus is more robust when it comes to demolding and welding, and is characterized by higher chemical and impact resistance. Because intricate injection-molded parts or parts with sharp angles are easy to demold, fluctuations in quality are minimized and yield is increased. Plexiglas 8N plus is suitable for a range of applications in automotive, architecture, and lighting, as well as household appliances.

Leave a Reply