Testing & Research Center to Install Lindner Washtech’s Plastic Washing System

Examining the behavior of different plastics during sorting and washing is a key focus currently at the NTCP (National Test Center Circular Plastics) in the Netherlands, Europe’s first independent testing and research center of its kind with facilities on an industrial scale. The goal is to optimize processes quantitatively, qualitatively and with more efficient energy use, in order to promote plastics recycling in line with the circular economy model.

Dutch and foreign clients are already showing great interest in the testing options, according to NTCP director Martine Brandsma, She expects that the modular design of the new Lindner Washtech plastic washing system, soon be installed, will make a significant contribution to their research and the optimization of various plastic streams.

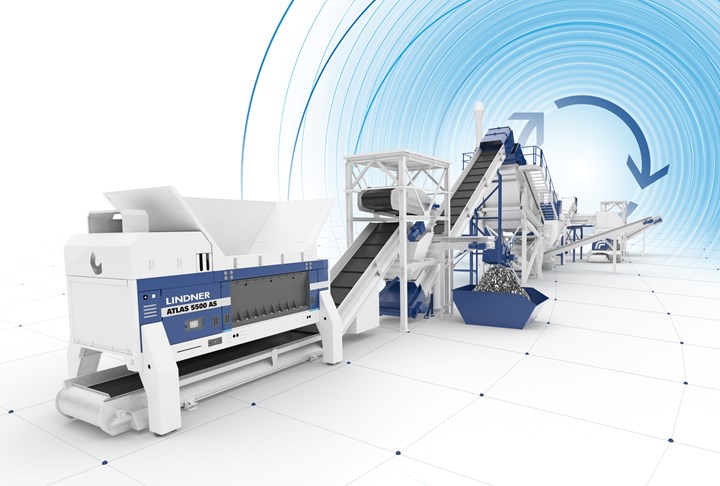

Photo Credit: Lindner Washtech

Friesland, a northern Dutch province, has been the home to NTCP, since its founding in 2018, which is reportedly Europe’s first independent testing and research center which can analyze heterogeneous plastic waste streams down to the smallest part. Rather than relying on usual test set-ups which are commonly used in research institutions, it is instead equipped with state-of-the-art facilities: raw, industrial, noisy and… using real waste.

NTCP’s concept is actually quite simple, according to Brandsma: the more plastic that enters the correct sorting stream and then takes the correct route to the relevant mechanical and chemical recyclers, the higher the percentage of plastics that remain in the loop. Though this may sound simple in theory, the reality is more complex. “It’s like a chess game, played on seven boards all at once – and chess moves are being made on each one.”

When one applies this to recycling, this means that everyone who takes part in the process – be it the collectors, sorters or recyclers – is in a constant state of development. This means that the system too is constantly changing. In order to examine individual or larger steps in the process, the NTCP has a 82.0 ft. by 65.6 ft. long, and 29.5 ft. high, industrial sorting system, which simulates the entire sorting process. The modular design allows for settings to be adapted to different testing requirements, which can then be analyzed in detail. In this way, one can also test how different sorting techniques interact.

NTCP’s current sorting system takes up half of the 10,763 sq.ft. of available production space. The other half is reserved for the new washing system, which will be commissioned from and installed by the plastic recycling specialist Lindner Washtech in August 2022. This modular system allows for each individual step of the washing process to be examined and quantified in detail. Freek Van Rhijn, technical director of the NTCP says, “Soon we will be able to simulate and optimize the entire washing process for all materials. From shredding, dry washing, cold and hot washing, density separation, mechanical and thermal drying, all the way to separating with a flake sorter. We can also focus on the detergents required and the environmental impact of using more or less water. How does washing by five or ten degrees less affect energy consumption? What ends up in the wastewater and how much does it cost to dispose of? With the new washing system, we can examine every single step, from sorting all the way to the final clean plastic flake.”

For several months, Van Rhijn has worked closely with Lindner Washtech’s engineers to develop the new plastic washing system. Harald Hoffmann, the firm’s managing director is happy to actively help shape this flagship project. He is convinced that the testing system as a whole will have a huge impact on the recycling industry and is a major leap forward. “The modular system will soon make it possible for different types of plastic to undergo different washing tests. This is made more feasible as the modules can be independently integrated into the process. In addition, the washing modules can be separately adapted to the requirements of each kind of plastic and its degree of contamination. This flexibility creates multiple opportunities for process optimization at every step of the way, while ensuring high-quality recycled material. This kind of research and testing not only actively contributes to recycling profitability, it also increases the rate of recycling and environmental protection,” says Hoffmann.

In addition to supplying the complex washing system, comprised of flexible and highly specialized components, Lindner Washtech is also including a universal plastic shredder from its Antares series, as well as a wet granulator. The washing process can be minutely adapted through its different components to suit any kind of input material and its varying degrees of contamination. To this end, a dry cleaner, pre-washer, friction washer or various hot-wash components are also available. The client can choose from various options when it comes to material separation and drying – which can be chosen to develop and design the optimal process for the material at hand.

The NTCP system will be equipped with a mechanical dryer, a step dryer, as well as thermal drying specifically for plastic film. Since the NTCP is an independent, not-for-profit organization, it reinvests all its profits, and equally addresses different organizations and stakeholders within the circular plastic recycling chain. Many national and international companies have already expressed an interest in collaborations and partnerships.

Freek van Rhijn, who came on board as technical director in October 2019, is not surprised that NTCP has logged so many orders since its inception: “When people come here, they can’t believe their eyes. They may have imagined a lab with a few small machines, but this is a real industrial plant. Everyone we speak to sees the benefits of operating at this scale.” Orders have come in from a variety of large and small firms, including sorters, recyclers, brand owners, retailers, packers and other stakeholders in the plastic recycling industry. These, alongside international brands, have all approached the NTCP with research and testing requests.

Lindner Washtech also intends to use this facility to further develop its washing components and to test prototypes. “In future, we want to make the most of the NTCP’s testing possibilities for our own research and development. We will also ensure that our latest innovations are made available to the NTCP for test runs. Ultimately, the entire plastics industry benefits from testing facilities of this magnitude,” says Lindner Washtech technical director Georg Krenn.

RELATED CONTENT

-

Commingled Plastic Waste: New Gold Mine for Automotive Processors

Instead of going to landfills, previously unusable mixed waste like auto shredder residue is yielding a new trove of inexpensive engineering resins for car parts. Sortation technologies derived from the mining industry can pull out usable ABS, PC, acrylic, PP, TPO, and PPO alloys.

-

AGS: A Molding Business Built on Recycling

AGS Technology Inc. in Schaumburg, Ill., was started in 1995 with a simple concept: to be the low-cost custom injection molder of automotive parts by using recycled plastics formulated to exacting quality standards.

-

Recycling Needs Drive Innovation in Sleeve Labels

Materials suppliers and film processors have been hard at work creating new label offerings compatible with PET bottle recycling.

Leave a Reply