Toray in Dutch Project for Aircraft Liquid-Hydrogen Tanks

Toray Advanced Composites, together with partners from industry and academia, has been awarded funding from the Dutch Ministry of Economic Affairs and Climate Policy’s Research and Development for Mobility for the development of a long-life, fully composite liquid hydrogen tank for civil aviation.

Hydrogen has been identified by the European Commission (EC) as a key priority to achieve the European Green Deal for a sustainable economy. By converting construction of the hydrogen tank from existing metallic solutions to composites, the liquid hydrogen (LH2) composite tank will achieve weight savings that enable the advancement of liquid hydrogen as a sustainable fuel source for civil aviation. This will lower the carbon footprint of air travel and increase and extend the flight range of aircraft fleet by reducing construction weight and cost.

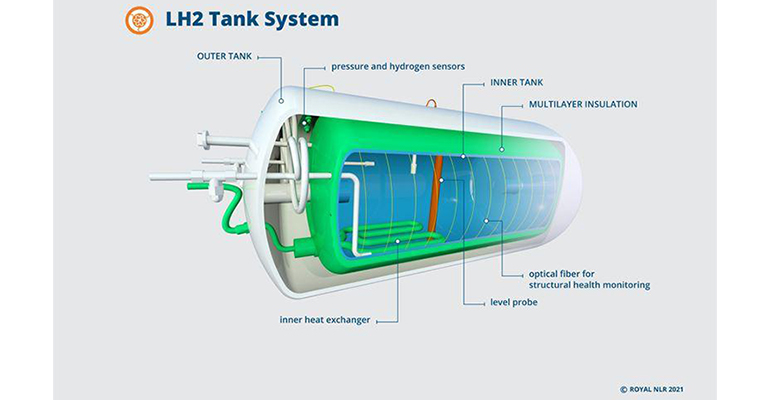

The cross-sector research aims to result in a lightweight composite tank that can withstand the incredibly low temperature of liquid hydrogen: -253°C. The project will focus on both composite tank construction, digital design strategies, and production technologies.

The consortium comprises of 13 partners across academia and industry: Aircraft Development and Systems Engineering (ADSE), Airborne, Bold Findings, Cryoworld, GKN Aerospace’s Fokker business, IT’S Engineering, Kok & Van Engelen Composite Structures (KVE), NLR, PhotonFirst Technologies, Somni Solutions, TANIQ, and Technical University Delft together with SAM|XL.

Frank Meurs, Managing Director, Toray Advanced Composites, said: “We are delighted to have been granted this funding. By joining together the best of Dutch industries and institutes in a unique consortium, we will contribute to the acceleration of hydrogen technology into aerospace as a sustainable fuel source for the future. This project underlines the commitment across the supply chain to drive forward sustainable propulsion technologies and is conducted in full alignment with the major aircraft and engine manufacturers.”

KVE has a worldwide recognized position on inductive assembly of carbon-fiber-reinforced thermoplastic composites, especially for aerospace applications. Well-known applications of KVE Induct technology can be found in the welded assembly of the rudders and elevators of the Gulfstream G650 and the Dassault Falcon 6X (performed under license by Fokker Aerostructures) and of the fuel-tank access panels for the Airbus A220 (performed under license by Aviacomp in France). All these KVE Induct applications make use of Toray materials. KVE has already validated the assembly method for cryogenic applications for a major oil & gas company. Thermoplastics have demonstrated superior performance under these conditions thanks to their inherent toughness and resistance against microcracking, which is not reduced by the welding process, said Toray.

Leave a Reply